MEDICAL AND AESTHETIC LASERS: Semiconductor diode laser advances enable medical applications

STEWART W. WILSON

While medical and aesthetic lasers have been largely limited to professional markets, technological advances in semiconductor diode sources are facilitating their migration to consumer markets. The U.S. Food and Drug Administration (FDA) approved the first-ever high-power diode laser product for hair removal in 1997 for the professional market. Nine years later, the company that had won the approval, Palomar Medical Technologies (acquired in 2013 by Cynosure [Westford, MA]), received FDA clearance for an over-the-counter (OTC) product for home use. In 2009, the company was the first to receive FDA clearance for a semiconductor laser-based OTC device for wrinkle removal, which it released to the consumer market in 2010. Advances in diode laser technology made both of these cases possible.

Selective photothermolysis and common chromophores

What makes a light source a good choice for a given application is the ability of its emitted light to interact with the tissue so as to achieve the desired effect. This is known as selective photothermolysis. Selectivity is accomplished by matching a specific wavelength of light to a chromophore—that is, the light-absorbent part of a molecule—in the tissue. During the absorption process, an electron is raised to its excited state from a ground state. In biological molecules that serve to capture light energy, the chromophore is the moiety that causes a conformational change of the molecule when hit by light. The energy directed into the target area produces sufficient heat to damage or alter the target while allowing the surrounding area to remain relatively untouched.

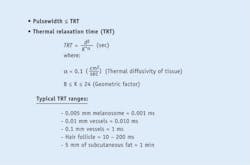

There are three light-related "knobs" to adjust when employing selective photothermolysis: wavelength, pulse duration, and energy level. As already described, the wavelength chosen assists in selective absorption of light by the target vs. the surrounding tissue. The pulse duration should be significantly shorter than the target's thermal relaxation time to avoid interaction with the area outside of the target. And the light energy selected should be higher than the damage threshold of the target. Proper selection of these critical parameters ensures the desired results.

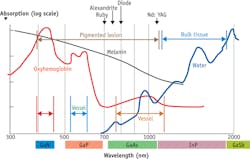

Common tissue chromophores targeted in dermatology applications are water (which makes up 70 percent of tissue), hemoglobin (blood), melanin (in the epidermis, pigmented lesions, and hair), lipids (subcutaneous fat and sebaceous glands), and protein (specifically, collagen). Each of these has a specific absorption spectra that corresponds to a semiconductor laser material able to produce the matching wavelength (see Fig. 1). And certain solid-state lasers used correlate with the materials and wavelengths. Because penetration depth depends highly on the wavelength of light, it must be considered when determining the energy needed for a particular application (see Fig. 2).Light source effectiveness

Semiconductor laser light sources have many advantages over other light sources for a variety of medical applications. Emphasis is on conversion efficiency, temperature sensitivity, and cost rather than beam quality and brightness, which tend to be the driving factors for applications outside biomedicine.

Lamps generate polychromatic divergent light, whereas lasers generate monochromatic light beams. Using flash lamps to target chromophores requires use of optical filters to narrow the spectral width—and reduces conversion efficiency to 10–20 percent. Additionally, a flash lamp-pumped laser has a conversion efficiency of around 1–10 percent. Semiconductor-based lasers, on the other hand, offer electro-optic conversion efficiency of 40–65 percent for wavelengths between 780 and 2000 nm. Recent advances have enabled efficiencies as high as 72 percent in the 780–1100 nm range, and 80 percent is theoretically possible.

Using a more efficient light source has two major advantages: The power supply needed to generate the optical energy is significantly less, and the required cooling system is smaller because there is less waste heat. Both factors allow for a more compact, cost-effective design. As an example, in comparing a system having a 25-percent vs. 65-percent conversion efficiency and producing the same optical power, the lower efficient system would require ~2X more electrical power and produce ~6X more waste heat.

Semiconductor lasers can produce a variety of monochromatic wavelengths and generate significant optical power in a small, compact footprint. By contrast, sources such as lamps tend to be not only inefficient, but also clumsy—and unable to focus on spot sizes smaller than 5 mm, which practically eliminates their use for tissue cutting and fiber delivery. Additionally, lamps are unable to generate pulses shorter than 1 μs, which makes them unsuitable for applications such as tattoo removal.

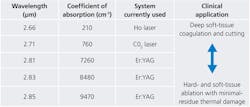

While gallium arsenide (GaAs)- and indium phosphide (InP)-based semiconductor lasers emit quite well, gaps have traditionally existed between their wavelength ranges. In recent years, though, more wavelengths have become available, and, for instance, 1200 nm (in the gap between GaAs and InP) has been demonstrated. Likewise, a system using gallium antimonide (GaSb) to generate type-I lasing (that is, typical laser operation in which light emission is generated by transition from the conduction to the valence band) in the 2000–3000 nm range has been shown to produce optical power between 0.5 and 2 W from a single device. These wavelengths are ideal for applications involving both soft and hard tissue, such as epidermal ablation, drug delivery, and dental treatment. Lastly, with the advent of type II interband and quantum cascade lasers (in which light is generated by transitions from a single level within the conduction band), even longer wavelengths—beyond 3000 nm (that is, mid IR)—are possible. It will be interesting to see what medical applications emerge for these longer wavelengths.

Direct and indirect configurations

Medical applications using semiconductor lasers as the main light source can be configured either directly (non-pumping) or indirectly (pumping)—the difference being whether or not light is being delivered directly to the treatment site.

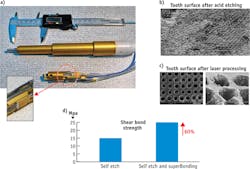

Indirectly configured semiconductor lasers are commonly used as optical pump sources for solid-state crystals—known as diode-pumped solid-state (DPSS) lasers. Another example of an indirect configuration is a diode-pumped fiber laser, which is also a solid-state laser, but in this case, the pumping gain medium is optical fiber. Choosing one of these would depend on the gain medium used and the wavelength needed.An example of a hard-tissue application would be in the creation of ultra-retentive dental surfaces—that is, the preparation of tooth surfaces to improve bonding with dental prostheses or composites. Retentive dental surfaces are conventionally formed using acid etch, which creates inconsistent surface structures and frequently results in the failure of dental restorations, especially those bonded to dentine. This failure rate can be as high as 40 percent. Using a laser for this same application creates a super-retentive bond on dentine and sclerotic dentine, and produces a 60-percent improvement in bond strength to dramatically reduce bonding failures, especially for dentine.

Some of the first direct-diode products to enter the consumer market have been demonstrated by Palomar Medical Technologies (with the PaloVia skin-renewing laser system in 2010) and Tria Beauty (then SpectraGenics, Dublin, CA, with the Tria hair removal system in 2008). PaloVia is the first home-use semiconductor laser device that is FDA-cleared for removing fine lines and wrinkles. This battery-operated, handheld device delivers 1410 nm in small spot patterns to the skin, creating a fraxel pattern of damage sites and thus initiating the body's natural healing response to generate more collagen while at the same time removing the wrinkles. Although Palomar was the first to gain FDA clearance for a home-use semiconductor laser for hair removal (2006), the purchase of Gillette by Procter & Gamble in 2005 significantly disturbed relationship and focus, thus enabling Tria Beauty to become the first and only company to deliver a semiconductor laser hair-removal system to the consumer market.

Impact for the future

An example of a direct-diode laser product that makes evident the significant improvements in semiconductor laser technology is the Vectus Laser designed by Palomar Medical Technologies in 2012. With Vectus, Palomar took direct aim at Lumenis' (Yokneam, Israel) LightSheer hair-removal system for the professional market (which Palomar actually designed in 1997 and sold to Coherent in 1999). Both systems emit at ~808 nm, but the Vectus uses an advanced design that requires four times fewer diode laser bars and produces significantly more optical energy in a wider treatment range. In a split-body direct-comparison study, the Vectus significantly outperformed LightSheer. This is not to trivialize the success of LightSheer at all; rather, the fact that LightSheer has been on the market since 1997 confirms the importance of using semiconductor laser technology for medical applications.

Semiconductor diode lasers already offer many advantages over other light sources for medical applications. Improvements in electro-optic conversion efficiency, optical power, and wavelength options make the technology ideal for targeting chromophores. Continued advancements will make it increasingly compelling.

REFERENCES

1. M. Inochkin et al., "High efficiency diode pumped Er:YLF laser with multi-wavelength generation," Proc. SPIE, 8234, 8234-4, session 1 (Jan. 22, 2012).

2. S. Wilson et al., "Long pulse compact and high brightness near 1-kW QCW diode laser stack," Proc. SPIE, 8241, 8241-14, session 3 (Jan. 22, 2012).

3. L. Shterengas et al., "High-power 2.3-um GaSb-based linear laser array," IEEE Photon. Technol. Lett. (2004).

4. A. Samad-Zadeh et al., "The influence of laser-textured dentinal surface on bond strength," American Dental Association, 2005-2007, IADR (2009).

5. J. Lowery et al., "Comparative study between the Vectus™ diode laser system and LightSheer™ Duet for long-term hair reduction in the axilla," Palomar Medical Technologies white paper (2013).

Stewart W. Wilson is a principal partner of Integrated Engineering Consulting LLC, Burlington, MA; e-mail: [email protected].