Laser-activated microsensor could help tailor kidney dialysis

Researchers at the Eindhoven University of Technology (TU Eindhoven; Netherlands) have developed a microsensor that can directly monitor and adjust the composition of kidney dialysis fluid. This could someday lead to patient-specific dialysis, which will remove a significant proportion of the serious side effects of the use of standard dialysis fluid.

Related: Highly specific fluorescent nanoparticles could enable personalized medicine

In kidney dialysis, a tube is connected to a blood vessel and the blood is passed along a membrane, with dialysate (dialysis fluid) on the other side. Because the concentration of salts in the blood is higher than in the dialysate, salt passes through the membrane and enters the dialysate. The rate at which this happens depends on the difference in concentration between blood and dialysate. Since the concentration of salts varies widely among different patients and the concentration in dialysate has the same standard value, the speed is often not ideal. This causes serious side effects, such as heart rhythm disturbance and renal bone disease. It would be better to continuously adjust the concentrations of salts in the dialysate so that they are optimal for the patient. However, this requires that the concentrations of salts in the dialysate can be monitored live.

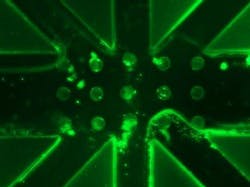

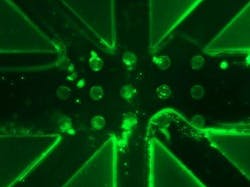

Recognizing the limitations, Manoj Kumar Sharma of TU Eindhoven's Department of Chemical Engineering and Chemistry developed a microsensor with a centrally positioned microchannel through which dialysate flows. He covered the walls of the microchannel with sensor molecules, which are only fluorescent in the presence of a salt, such as sodium. The more sodium there is in the dialysate, the stronger the fluorescence. To reinforce this effect, he introduced micropillars into the microchannel, resulting in even more surface covered with sensor molecules.

With the microsensor, a laser light shines on the microchannel to activate the fluorescence of the sensor molecules. Sharma captures this fluorescence using glass fibers that he connected to the channel in the microsensor. Then, light passes through the fibers to a spectrometer for analysis. The laser light, which is of a different wavelength, is first filtered out. Then, based on the measured intensity of the fluorescence, the sodium concentrations can be read out.

It is important to ensure that the sensor molecules are not disturbed by other salts to make pure measurement of the concentration of a specific salt is possible. The microsensor system, which measures approximately 5 × 2 cm, is able to measure sodium (the most important salt in the blood) accurately and in real time. Sharma expects that it will be relatively easy to extend the microsensor with channel sections coated with other photoinduced electron transfer (PET) sensor molecules, which are sensitive to other essential salts such as potassium and phosphate.

Sharma thinks that the technique has a very good chance of being used in dialysis machines, as it is low-cost, stable, and very accurate. In addition, he expects that the size of his sensor system can be further reduced (to about 1 × 1 cm) to facilitate integration into dialysis machines. His technique may also eventually become part of a portable artificial kidney—a solution that will significantly ease the life of kidney patients.

Sharma, who was awarded a Ph.D. degree for this research on March 29, 2018, carried out the research in collaboration with Maastricht UMC + and TNO, and with the support of the Dutch Kidney Foundation.

For more information, please visit www.tue.nl.