Flat, lensless fluorescence microscope has several bioimaging uses

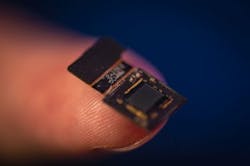

A team of engineers at Rice University (Houston, TX) has developed a wide-field fluorescence microscope thinner than a credit card, small enough to sit on a fingertip, and capable of micrometer resolution over a volume of several cubic millimeters. Called FlatScope, the device eliminates the tradeoff that hinders traditional microscopes in which arrays of lenses can either gather less light from a large field of view or gather more light from a smaller field.

Related: Flat microscope in development aims to restore sight and sound to the disabled

The engineers began developing the device as part of a federal initiative by the Defense Advanced Research Projects Agency (DARPA; Arlington, VA) as an implantable, high-resolution neural interface. The researchers claim FlatScope, an advance on the labs' earlier FlatCam, could also be used as an implantable endoscope, a large-area imager, or a flexible microscope.

Traditional fluorescence microscopes pick up fluorescent signals from particles inserted into cells and tissues that are illuminated with specific wavelengths of light. The technique allows scientists to probe and track biological agents with nanometer-scale resolution. But like all traditional microscopes, telescopes, and cameras, their resolution depends on the size of their lenses, which can be large and heavy and limit their use in biological applications.

FlatScope uses the same charge-coupled device (CCD) chips found in all electronic cameras to capture incoming light. Its field of view equals the size of the CCD sensor, which can be as large or as small as required. It's flat because it replaces the array of lenses in a traditional microscope with a custom amplitude mask. This mask, which resembles a barcode, sits directly in front of the CCD. Light that comes through the mask and hits the sensor becomes data that a computer program interprets to produce images. The algorithm can focus on any part of the three-dimensional (3D) data the scope captures and produce images of objects smaller than a micron anywhere in the field.

"A camera in your mobile phone or DSLR typically gets on the order of 100 µm resolution," explains Rice University engineer Jacob Robinson. "When you take a macro photo, the resolution is about 20 to 50 µm. I think of a microscope as something that allows you to image things on the micron scale. That means things that are smaller than the diameter of a human hair, like cells, parts of cells or the fine structure of fibers."

Achieving that resolution required modifications to the FlatCam mask to further cut the amount of light that reaches the sensor as well as a rewrite of their software, Robinson says. "It wasn't as trivial as simply applying the FlatCam algorithm to the same techniques we used to image things that are far away," he says.

The mask is akin to the aperture in a lensed camera that focuses light onto the sensor, but it's only a few hundred micrometers from the sensor and allows only a fraction of the available light to get through, limiting the amount of data to simplify processing.

"In the case of a megapixel camera, that computational problem requires a matrix of a million times a million elements," Robinson says. "It's an incredibly big matrix. But because we break it down through this pattern of rows and columns, our matrix is just one million elements."

That cuts the data for each snapshot from 6 TB to a more practical 21 MB, which translates to short processing times. From early versions of FlatCam that required an hour or more to process an image, FlatScope captures 30 frames of 3D data per second.

Ashok Veeraraghavan, another Rice engineer involved in the work, says the burgeoning Internet of Things (IoT) may provide many applications for flat cameras and microscopes. That in turn would drive down costs. "One of the big advantages of this technology compared with traditional cameras is that because we don't need lenses, we don't need postfabrication assembly," he says. "We can imagine this rolling off a fabrication line."

The researchers' primary targets for FlatScope are medical uses, from implantable scopes for the clinic to palm-sized microscopes for the battlefield.

The researchers noted that while their current work is focused on fluorescence applications, FlatScope could also be used for bright-field, dark-field and reflected-light microscopy. They suggested an array of FlatScopes on a flexible background could be used to match the contours of a target.

Full details of the work appear in the journal Science Advances.