SPECTROSCOPY: VCSELs benefit TDLAS combustion measurements

Researchers at Physikalisch-Technische Bundesanstalt (PTB; Braunschweig, Germany), TU Darmstadt (Darmstadt, Germany), and the University of Duisburg-Essen (Duisburg, Germany) have developed and demonstrated the first tunable diode laser absorption spectroscopy (TDLAS or TDLS) system incorporating vertical-cavity surface-emitting lasers (VCSELs) for water (H2O) vapor measurements in internal-combustion (IC) engines.1 The system improves over former TDLAS configurations using distributed-feedback (DFB) laser diodes.

Exhaust-gas recirculation (EGR) in IC engines increases the quantity of inert gas in the cylinder by (1) returning gas from the exhaust duct to the intake (external EGR) or (2) by retaining residual gas burned in the cylinder at the end of the exhaust stroke (internal EGR). This EGR greatly affects combustion; exact knowledge of the amount as well as the temporal and spatial distribution of the residual gas before ignition is important. Measuring the most important EGR gas species—H2O and carbon dioxide—is not possible using fluorescence except at unrealistically high temperatures. Fortunately, both gases have relatively high near-infrared (NIR) absorption cross-sections, allowing absorption-based detection in the NIR.

Why TDLAS?

Broadband absorption spectroscopy (BAS) and fixed-wavelength absorption spectroscopy (FWAS) can measure these EGR species, but have limited specificity and complex calibration routines that cannot be easily adjusted for rapid and strong transmission losses or for strong luminous background emissions.

Alternatively, a certain TDLAS variant called direct TDLAS (dTDLAS) can effectively correct for transmission losses (from laser attenuation or particulates on the signal access windows) as well as suppress luminescence from flames or hot surfaces. Furthermore, dTDLAS can enable calibration-free concentration measurements and—important for high-speed engine measurements—high-resolution spectral absorption line profiles at multi-kilohertz scanning speeds that also yield data on gas temperature, pressure, and background emissions.

The researchers developed a DFB-laser-based dTDLAS instrument that determined water concentration in the compression stroke of an IC engine with a time resolution of 250 μs. However, the limited dynamic range of the 30 mW telecommunication-type DFB used initially decreases significantly at higher modulation frequencies and was not able to capture the spectral absorption lines at the increased pressures seen in the second half of the compression stroke of the engine.

VCSEL advantages

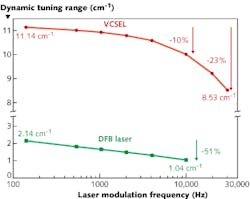

Even though the 1369.84-nm-center-wavelength VCSEL used next in the absorption-spectroscopy setup only had a power output between 0.17 and 0.25 mW, its high modulation bandwidth and 5-8X wider tuning range (from 1368.2 to 1371.3 nm) is advantageous for TDLAS measurements (see figure). When the modulation frequency is increased from 0.1 to 10 kHz, the DFB laser tuning range decreases by 50% (5% per kilohertz), while the VCSEL tuning range is significantly higher and also decreases by only 10% over the same modulation frequency range. The VCSEL thus spans the full absorption line in the desired pressure range, even with 30 kHz modulation.

In the experimental setup, the Peltier-temperature-stabilized VCSEL is current-modulated with a sawtooth signal and coupled into a singlemode fiber. The light exiting the fiber is then collimated and transmitted through the engine’s combustion chamber. A photodiode captures the transmitted signal, which is converted to a voltage signal, digitized, and fitted to a measured H2O spectrum to determine concentration.

Scatter plots of water-concentration values at pressures of several bar for 4 kHz modulation rates (the upper limit for the DFB laser) showed a standard deviation of 2970 ppm for the DFB laser-based system compared to just 1155 parts per million (ppm) for the VCSEL-based system. Scatter diminishes significantly as modulation rates rise to 10 kHz, illustrating the benefit of VCSEL-based TDLAS measurements for high-pressure engine-combustion measurements.

TDLAS offers great advantages against other techniques, especially because there is no need for sensor calibrations, which are difficult in harsh environments like IC engines, says Oliver Witzel and Volker Ebert at PTB. Using VCSELs and their much larger modulation depth is valuable in high-pressure environments, and their low power can be compensated with fiber-coupled optical amplifiers already available for this wavelength region. In addition, VCSEL-based spectrometers have the ability to capture several absorption features at once. Witzel and Ebert add that with these qualities, VCSELs will become an important tool for simultaneous temperature and concentration measurements in the future.

REFERENCE

1. O. Witzel et al., Opt. Exp., 21, 17, 19951 (August 26, 2013).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.