Engineers at Spectra-Physics Lasers (Mountain View, CA) have demonstrated more than 10 W of Q-switched, ultraviolet (UV) output from a diode-pumped laser, setting a new record for a commercial, all-solid-state laser operating at 355 nm (see Fig. 1). The laser will be introduced at CLEO 2001 (May 6-11, Baltimore, MD), according to marketing manager Mark Kierstead. The specified power will be 8 W at 355 nm with an M2 of less than 1.3. The pulse repetition rate is adjustable from 10 to 100 kHz, with maximum output power at 30 kHz.

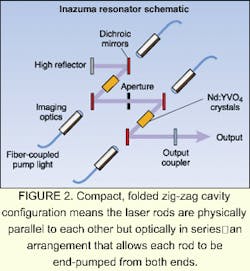

The Inazuma laser, which is based on Nd:YVO4, is the first to utilize Spectra-Physics' novel "periodic resonator" technology, which is intended to avoid a design tradeoff that had previously limited the output power of high-beam-quality, all-solid-state UV lasers. Some laser manufacturers achieve high beam quality by using a cavity configuration based on end pumping of the laser crystal, explained Kierstead. This approach is optically very efficient, can deliver a diffraction-limited beam (M2 close to 1) with excellent pulse-to-pulse stability, he said. Moreover, this design also allows the pump diodes to be located in the power supply, simplifying replacement and avoiding realignment of the sealed laser cavity. Even when the laser rod is pumped from both ends, however, there is a limit to the power that can be coupled into the rod without causing cavity instability problems. This problem has kept end-pumped lasers to lower power levels (4 W at 355 nm). Side-pumped resonator designs can be easily scaled to much higher power, but suffer from thermal management issues, low efficiency, and practical problems associated with replacing failed diodes.Spectra-Physics' answer to this limitation is its periodic resonator—a compact, folded cavity in which two (or more) laser rods are placed in a zig-zag configuration. The rods are physically parallel but optically in series—an arrangement that allows each rod to be end-pumped from both ends (see Fig. 2). With two rods and four diode bars, Inazuma produces 35 W in the near infrared, 20 W at 532 nm, and 8 W at 355 nm—all with M2 > 1.3. Kierstead says this new end-pumped design also features very high pulse-to-pulse stability and excellent beam pointing. In addition, the use of a modular system to generate the visible and UV wavelengths allows end users to quickly switch between the infrared, green, and UV outputs.

The combination of high power and beam quality is very desirable for several key applications in precision materials processing, including microvia drilling. In this application, 355-nm lasers currently are preferred for drilling the copper layers, but have not had the necessary power to drill the organic layers at cost-effective speeds. As a result, many microvia drilling machines use a hybrid combination of a 355-nm solid-state laser and a carbon dioxide laser. With the advent of higher-power all-solid-state systems, end users should soon see the benefits of single-laser drilling stations. Several other applications have already been evaluated in Spectra-Physics' applications lab, including trimming, cutting and patterning of polyimides used in flex circuits, as well as the machining and dicing of semiconductor wafers.