EV Group and SwissLitho develop 3D nanoimprint lithography system with 1 nm accuracy

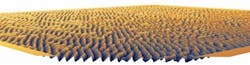

EV Group (EVG; St. Florian, Austria), a supplier of wafer bonding and lithography equipment for the MEMS, nanotechnology, and semiconductor markets, and SwissLitho (Zurich, Switzerland), a manufacturer of nanolithography tools, announced a joint solution to enable the production of 3D structures down to the single-nanometer scale. Initially demonstrated within the "Single Nanometer Manufacturing for Beyond CMOS Devices (SNM)" project funded by the Seventh Framework Program of the European Union, the joint solution involves SwissLitho's novel NanoFrazor thermal scanning probe lithography system to produce master templates with 3D structures for nanoimprint lithography (NIL), and EVG's HERCULES (trademarked) NIL system with SmartNIL (trademarked) technology to replicate those structures at high throughput.

RELATED ARTICLE: Nanoimprint diffraction gratings improve solar-cell efficiency

EVG and SwissLitho will initially target the joint solution for developing diffractive optical elements and other related optical components that support photonics, data communications, augmented/virtual reality (AR/VR), and other applications, with the potential to expand into biotechnology, nanofluidics, and other nanotechnology applications.

As part of the joint solution, SwissLitho's NanoFrazor system will be used to create imprint masters. Compared to conventional approaches, including electron beam (e-beam) and grayscale lithography, the technology has the unique ability to print 3D structures with unsurpassed accuracy. EVG's HERCULES NIL system will then be used to create working templates for production use, cost-effectively and at high throughput, using the company's proprietary large-area nanoimprint SmartNIL technology.

Thermal scanning probe lithography, the technology behind the NanoFrazor, was invented at IBM Research in Zurich and acquired by SwissLitho AG. This maskless, direct-write lithography approach involves spin-coating a unique, thermally sensitive resist onto the sample surface before patterning. A heated ultra-sharp tip is then used to decompose and evaporate the resist locally while simultaneously inspecting the written nanostructures. The resulting arbitrary resist pattern can then be transferred into almost any other material using lift-off, etching, plating, molding or other methodologies.

SOURCE: Swiss Litho; https://swisslitho.com/ev-group-and-swisslitho-to-develop-joint-nanoimprint-lithography-solution-for-3d-optical-structures-with-single-nanometer-accuracy/

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.