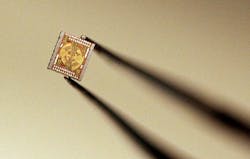

Researchers at Princeton University (Princeton, NJ) have drastically shrunk terahertz source and detection equipment, moving from a tabletop setup with lasers and mirrors to a pair of microchips small enough to fit on a fingertip. In two articles recently published in the IEEE Journal of Solid State Circuits, the researchers describe one microchip that can generate terahertz waves, and a second chip that can capture and read intricate details of these waves.

RELATED ARTICLE: Terahertz QCL produces evenly spaced frequency comb good for detecting explosives

"The system is realized in the same silicon chip technology that powers all modern electronic devices from smartphones to tablets, and therefore costs only a few dollars to make on a large scale," said lead researcher Kaushik Sengupta, a Princeton assistant professor of electrical engineering.

Terahertz waves have less energy than X rays and do not damage human tissue or DNA. They also interact in distinct ways with different chemicals, so they can be used to characterize specific substances through terahertz spectroscopy. The challenge has been that generating a broad range of terahertz waves and interpreting their interaction with a target requires a complex array of equipment such as bulky terahertz generators or ultrafast lasers. The equipment's size and expense make the technology impractical for most applications.

In September, Sengupta's team reported a way to reduce the size of the terahertz generator and the apparatus that interprets the returning waves to a millimeter-sized chip. The solution lies in re-imaging how an antenna functions. When terahertz waves interact with a metal structure inside the chip, they create a complex distribution of electromagnetic fields that are unique to the incident signal. Typically, these subtle fields are ignored, but the researchers realized that they could read the patterns as a sort of signature to identify the waves. The entire process can be accomplished with tiny devices inside the microchip that read terahertz waves.

Daniel Mittleman, a professor of engineering at Brown University, said the development was "a very innovative piece of work, and it potentially has a lot of impact." Mittleman, who is the vice chair of the International Society for Infrared Millimeter and Terahertz Waves, said scientists still have work to do before the terahertz band can begin to be used in everyday devices, but the developments are promising.

On the terahertz-generation end, much of the challenge is creating a wide range of wavelengths within the terahertz band, particularly in a microchip. The researchers realized they could overcome the problem by generating multiple wavelengths on the chip. They then used precise timing to combine these wavelengths and create very sharp terahertz pulses.

SOURCE: Princeton University; http://www.princeton.edu/main/news/archive/S48/64/99Q68/?section=topstories