Laser-based ultrasound detection system identifies deadly water bacteria in hours, not days

A Photonics PPP Horizon 2020-funded water-safety project called ‘WaterSpy’ has developed a portable laser-based water quality analyzer to be used at critical points on a water distribution network to provide a reading on deadly bacteria in a matter of hours rather than days. Despite high compliance monitoring from water companies across Europe, deadly disease outbreaks are a common occurrence, according to a 2017 World Health Organization (WHO) report. Monitoring three of the most deadly bacteria--E Coli, Salmonella, and Pseudomonas Aeruginosa--in drinking water can take 3 days, with results usually delivered after an exposure has occurred.

RELATED ARTICLE: Fiber-optic sensor identifies E. coli bacteria in less than 20 minutes

With its prototype ready, the WaterSpy team will take their device to be tested in two sites in Genova: the Prato Water Treatment Plant, and the entry point of the Genova water distribution network. Since the concentration of contaminants can be very low, this deadly trio is often hard to detect. The current process involves water samples being taken and sent to a remote laboratory, and with bacteria traces often so small, a period of 24 hours is needed to allow the pathogens to cultivate.

"Most water companies," Alessandro Giusti, (PhD) manager within the coordinating organization explains, "will struggle to meet these new strict laws if they simply carry on as they are right now. Current technologies for bacterial diagnosis are very slow and some of the faster ones are still not precise enough. So, new technologies, such as WaterSpy are needed."

Using the latest photonics technology, the device--a laser configuration combined with new photodetectors and ultrasound particle manipulation--is suitable for inline, field measurements. "Although the water that comes out of your tap is safe before it gets to you, water utilities, public authorities and regulators rely heavily on frequent sampling and laboratory analysis. This is both time-consuming and expensive. WaterSpy intends to speed this up, make huge savings and provide real-time critical data. The speed of our device is unprecedented: a full sample analysis will take up to 6 hours to complete so comparing this to the 2-3 days it takes with existing methods, we expect results 12 times faster than the current standard. WaterSpy is relatively cheap and will adhere to incoming regulatory requirements in terms of specificity and sensitivity levels."

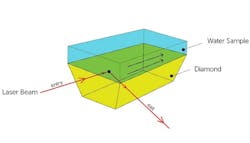

It works by first gathering the small traces of bacteria, and then detecting them with a laser. "Unfortunately," Giusti said, "water itself is a very strong absorber of infrared light and special techniques have to be applied." In the same way that sand resonates in gathered patterns on top of a ceramic tile when a sound wave is applied, ultrasound is used to congregate the bacteria in the water sample in order to enhance the detection and sensitivity. The WaterSpy device then detects the bacteria by exploiting a measurement technique called Attenuated Total Reflection (ATR), enabling a sample to be examined directly in the liquid state.

Beams of infrared light are sent into a diamond over which the water flows. The IR light then reflects off the internal surface in contact with the water sample, before being collected by a detector as it exits the crystal.

Coordinated by CyRIC, Cyprus Research and Innovation Center Ltd the WATERSPY consortium secured a grant from the European Commission under the H2020 funding program. Waterspy is comprised of 9 partners with participants from 7 different European countries: (Italy) Consiglio Nazionale Delle Ricerche; IREN SPA; (Switzerland) Alpes Lasers SA; (Greece) National Technical University of Athens; A.U.G Signals Hellas Technology Developments and Applications; (Austria) Technische Universitaet Wien; (Poland) Vigo Systems SA; (Germany) Friedrich-Alexander-Universitaet Erlangen Nuernberg.

SOURCE: WaterSpy; http://waterspy.eu

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.