Optical Frequency Combs: Smallest chip-based ‘microcomb’ consumes just 1 W in a 1 cm3 package

While chip-based optical frequency combs operating in the dissipative Kerr soliton (DKS) mode have been demonstrated, these coherent soliton “microcombs” typically require high threshold powers (a few milliwatts) that are difficult to achieve in silicon-photonics-based lasers. As a result, chip-based approaches have previously required optical pumping with external, bulky standalone laser modules. These modules in turn require additional optical amplifiers to counteract the high coupling losses and low quality (Q) factors of the integrated photonic microresonators used to initiate soliton formation.

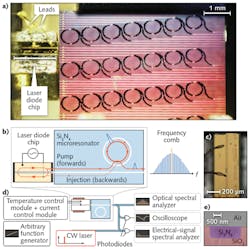

Building on recent advances in the pursuit of ultralow losses in silicon nitride (Si3N4) waveguides, researchers from the Swiss Federal Institute of Technology Lausanne (EPFL) and the Russian Quantum Center (Moscow) have built a compact (1 cm3), low-power-consumption (1 W electrical), high-performance (sub-100 GHz comb spacing) integrated Si3N4 microresonator-based soliton microcomb in conjunction with a commercially available chip-based laser diode.1 The researchers say it is the smallest Kerr soliton microcomb to date and, unlike a recently demonstrated device, requires no Vernier filters or temperature tuning mechanisms.2

Optical frequency generation and self-injection locking

One of the key challenges to achieve soliton microcomb generation at low power was to fabricate the microresonator with ultralow losses. The Si3N4 microresonators featuring smooth sidewalls were fabricated using the photonic Damascene reflow process, enabling the high-Q factor (>10 million) used to generate a microcomb operating at electronically detectable repetition rates (<100 GHz) with a commercially available laser diode chip.

A critical injection locking mechanism allows soliton formation to occur with a multifrequency indium phosphide (InP) chip-based laser diode. By tuning the current of the InP laser diode, the lasing frequency coincides with selected resonances of the microresonator and a small fraction of light gets scattered back to the laser diode. This leads to switching from a multifrequency emission to single-mode operation indicating self-injection locking, an important phenomenon to stabilize the laser diode and enable high-coherence lasing (see figure).

The small phase difference between emitting and backscattered light provide the freedom to detune the laser frequency from the microresonator’s resonance, which is crucial for Kerr frequency-comb generation due to its existence on the effectively red detuned side. Initially, the self-injection locked state is switched to a chaotic comb (modulation instability), and eventually to coherent soliton microcombs by changing the current of the laser diode. The direct fast optical feedback from the microresonator not only stabilizes the laser diode, but the solitons are generated without any active electronics stabilization or additional modulators, greatly reducing the operational complexity.

Soliton microcombs operating at 149 GHz and 88 GHz have been demonstrated via simple current tuning of the laser diode, eliminating the need for bulky external pump lasers and showing high performance for a chip-based integrated device in such a small footprint. Such an integrated chip-scale device promises myriad applications in future datacenter interconnects, coherent telecommunication, lidar, and spectroscopy.

“The high-losses in Si3N4 waveguides prevented the full photonic integration of the optical frequency combs. This longstanding problem was solved by optimizing the Si3N4 fabrication using a patented method called ‘the photonic Damascene process’ developed at EPFL,” says professor Tobias J. Kippenberg, the head of the Laboratory of Photonics and Quantum Measurements at EPFL. “The photonic integrated soliton microcomb driven by a chip-scale laser diode with simplified operation will unlock their potential use in everyday applications, which were limited to the laboratory until now.”

REFERENCES

1. A. S. Raja et al., Nat. Commun., 10, 680 (Feb. 8, 2019); www.nature.com/articles/s41467-019-08498-2.

2. B. Stern et al., Nature, 562, 401–405 (2018).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.