Optical surface analyzers become precision manufacturing tools

Nondestructive metrology techniques are moving out of the lab and onto the factory floor for real-time assessment of thin films and other complex coatings.

Understanding the optical surface properties of modern materials has become a critical part of manufacturing in industries ranging from microelectronics to biomedicine. With the increasing complexity of manufacturing processes and products comes the need for extremely precise analysis and control of surface properties such as film thickness and chemical composition, often in real time and online. This trend is paving the way for nondestructive optical metrology techniques to move into volume production environments, particularly those involving thin films.

Historically, the most common techniques for true surface analysis have been mass spectrometry and electron spectroscopy, which can routinely measure the chemical and physical composition of the outermost layers of any solid material. Using the latest instrumentation, it is now possible to identify and quantify elements in surfaces down to parts-per-billion detection limits or to map the distribution of individual atoms on surfaces.

But these techniques have limitations: in addition to being primarily lab-based, which means they are designed to work with isolated samples outside of the production environment, they essentially destroy the samples they measure. Even atomic-force microscopy, which has long been considered an essential tool for surface inspection and analysis, and laser-induced breakdown spectroscopy, which is emerging as a precision analytical technique for industrial applications because it requires only very small samples, can alter the optical properties of sensitive samples, making these approaches less practical for online analysis of thin-film products such as semiconductor chips, flat-panel displays, and data-storage media heads.

“The semiconductor industry continues to push toward thinner and thinner films,” said James Hilfiker, an engineer with J.A. Woollam Co. (Lincoln, NE), which develops and manufactures spectroscopic ellipsometers. “SIMS analysis and other sputter depth-profiling techniques pretty much ruin a sample, while with scanning-electron microscopy and transmission-electron microscopy you often have to cut the sample and scan it from the side. How often can you do that in a production environment?”

These issues have prompted the development and refinement of more-robust optical instruments that are particularly suited to analyzing thin films in a production environment. Such devices, which include scatterometers, reflectometers, profilometers, and ellipsometers, are now able to provide real-time surface-quality and film-thickness data for a broad range of manufacturing applications beyond microelectronics: pharmaceuticals, photography, construction, forensics-even planes, trains, and automobiles, for corrosion protection.

“Using optical fibers as a means of moving light around has opened up whole new ways of making measurements and added a new versatility and flexibility, and thin-film analysis has really benefited from this,” says Leeward Bean, vice president of sales for Ocean Optics (Dunedin, FL). “You couldn’t do this with the old bench instruments.”

Thin-film metrology

Most nondestructive surface-analysis techniques are based on reflectance. For example, optical profilometers, which measure surface roughness by means of optical interferometry, provide noncontact measurement of surface topography profiles for applications such as thick-film measurements, IC packaging, and tribology. The LaserScan surface profilometer from Solarius (Sunnyvale, CA), for example, features vertical resolutions down to 0.01 µm and measurement ranges up to 10 mm (see Fig. 1). In IC packaging, the LaserScan is used to analyze warpage, lead coplanarity, laser marking, and contact roughness; in thick-film metrology applications, the system provides highly accurate measurement of production parameters such as printed resistor layers, conductor paths, and laser trim structures.

Spectroscopic reflectometers such as the NanoCalc have been a mainstay of optical semiconductor metrology for many years, as has ellipsometry performed at a single wavelength and a fixed angle of incidence. More recently, however, multiwavelength spectroscopic ellipsometry has emerged as a precision tool for measuring the consistency of thin-film coatings and their optical properties. Ellipsometry was first discovered more than 100 years ago, but it wasn’t until the last decade that advances in electronics and computing have made it applicable to a broad range of industries.

In general, ellipsometry is based on the measurement of the elliptical states of polarized light reflected from or transmitted through a material surface. By studying interface-induced changes-specifically, the phase differences in the interaction between the material and polarized light-one can measure fundamental optical properties of physical systems, including the refractive index, absorption coefficient, surface roughness, alloy concentrations, and thickness. Single-wavelength ellipsometry can measure only two parameters, while spectroscopic ellipsometry can analyze complex structures such as multilayers, interface roughness, inhomogeneous layers, and anisotropic layers. In addition to its nondestructive nature, the advantages of ellipsometry are its high sensitivity (due to the measurement of the phase of the reflected light), large measurement range (from fractions of single layers to micrometers), and the ability to control real-time complex processes.

One company at the forefront of spectroscopic ellipsometry technology is J.A. Woollam, founded in 1987 by John Woollam, a professor of engineering at University of Nebraska (Lincoln, NE) and a leading researcher in this field. Woollam had used ellipsometry at UNL to study new semiconductor materials for high-frequency electronic devices, such as gallium arsenide and aluminum gallium arsenide, but he became frustrated by the time it took to acquire data using the ellipsometers and computers of the time: roughly 20 minutes for a single wavelength and several hours or a day for a full spectrum. So he decided to automate the process.

“Our company saw a definite need for very fast measurements with ellipsometry,” Hilfiker said. “Before that, you would put a sample on and wait an hour (or more) to get the results. So we did a lot of research in the 1990s to develop a faster spectroscopic ellipsometer for real-time process control. Instead of taking the sample out of the chamber, many customers want to measure it during the process. Using diode arrays or CCD collection, we can now get data in less than one second, which opens up a lot of new applications.”

According to Hilfiker, these applications include semiconductor manufacturing (for controlling thin-film properties in silicon ICs and for developing new photoresists), data storage (to measure the very thin carbon coatings on read/write heads), flat-panel displays, magneto-optic materials, ferroelectrics, and other protective coatings, such as on a razor blade or tractor part (see Fig. 2).

Emerging thin-film applications include the study of biomaterial interfaces, such as protein attachment to different types of surfaces. Using spectroscopic ellipsometry, Woollam is studying and characterizing molecular layers as thin as a single molecule with dimensional scales of a few nanometers.

“When something gets really thin, other analysis techniques fall apart,” Hilfiker said. “But spectroscopic ellipsometry measures phase information that is very critical to thin films less than 10 nm.”

All-in-one

Some instrument developers believe that the best way to provide the most information about a surface or coating is to combine several techniques, primarily because different defects can have a signature that is easily detected by one optical technique but invisible to another.1 For instance, while a profilometer can detect, say, a hillock or similar problem on a transparent wafer, a stain is visible only to an ellipsometer or reflectometer. Similarly, a shallow pit that may not be visible to a scatterometer can be clearly detected by a profilometer.

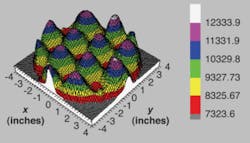

This was the idea behind the Optical Surface Analyzer (OSA) from Candela Instruments (Fremont, CA; now a division of KLA-Tencor). The OSA combines an ellipsometer, reflectometer, scatterometer, and optical profiler into a single optical head, enabling the simultaneous detection and classification of a broad range of surface defects. The OSA consists of a laser producing a beam that propagates at a high angle of incidence, allowing it to interact with the wafer substrate surface and reflecting (and scattering) from the surface. The reflected beam goes to an optical profiler, a reflectometer, and an ellipsometer channel. The scattered beam is detected via an integrating sphere. In addition, the OSA uses a spatial filter to block the signal from the back surface of a transparent wafer, making it possible to see only the defects on the top surface. This technique has been successfully used to detect and classify pits, bumps, stains, scratches, particles, and crystal defects (see Fig. 3). According to Steven Meeks, vice president of technology for Candela, the OSA can inspect transparent wafers that are used in high-brightness LEDs, laser diodes, and next-generation ICs, such as those used in hybrid cars, radar systems, and power supplies.

“This is a multifunctional tool,” he said. “Some customers measure topography to determine the roughness of their substrate, while others are interested in micropipes, such as how many are on the surface and their location. But it has become the standard in the data-storage, defect-detection, and process-control fields, and the compound-semiconductor industry has similar needs. They can benefit from the same inspection technology to improve their yields and have faster process development.”

REFERENCE

1. S. Meeks, Laser Focus World 39, 105 (July 2003).