SPECTROMETERS: Digital-transform spectroscopy shows its versatility

A new breed of portable, low-cost, high-performance devices-digital-transform spectrometers based on MEMS technology-is changing the molecular-spectroscopy industry.

MIKE BUTLER, YARIV GELLER, and MOULI RAMANI

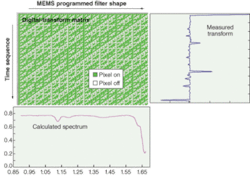

A common dispersive method for spectroscopy instruments is the optical multichannel analyzer (OMA) typically implemented using a detector array. In the visible part of the spectrum, the proliferation of digital cameras has made diode-array technology widespread and inexpensive, enabling the development of a low-cost OMA spectrometer market. Nevertheless, as a silicon-based technology, the digital camera chip is limited in its wavelength-range responsiveness, making it unsuitable for the near-IR and IR regions of the spectrum. Although near-IR indium gallium arsenide or lead selenide diode arrays are available, their high prices constitute a dominant cost component in near-IR and IR spectrometers. Thus, OMA spectrometers in the near-IR and IR spectral region, where the predominant chemical signatures exist, remain prohibitively expensive for many applications. A new approach based on MEMS technology overcomes many of these problems.

Digital-transform spectrometer

Using MEMS microfabrication techniques, a group at Stanford University (Palo Alto, CA) led by David Bloom demonstrated a grating light-valve device in which groups of micromechanical elements could be actuated together by applying a voltage-to create a diffracting “pixel.”1 With multiple such pixels replicated along a MEMS chip, a programmable spectral mask can be created on the fly. By dispersing the spectrum across the MEMS chip, discrete sections of the spectrum can be “blocked” by diffracting light into higher orders, while others can be reflected with no diffraction loss.

A variant of the original Bloom device was developed by Sandia National Laboratories and further refined by Polychromix to create synthetic chemical spectra using an array of individually controllable diffraction elements.2, 3, 4

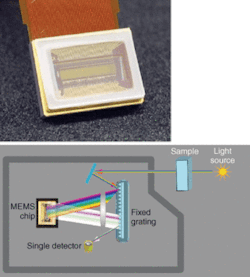

The digital-transform spectrometer (DTS) is a dispersive spectrometer that spreads the spectrum collected from the sample across a diffractive-MEMS chip’s pixels (see Fig. 1). Wavelengths that encounter a pixel that is set to diffract light are scattered and dumped inside the device. Other spectral regions that impinge upon pixels set to a nondiffracting state are reflected and recombined by the fixed grating and then collected by a single photodetector.

This configuration enables the selective measurement of the total power in a desired spectral region or any combination of regions, using an inexpensive single detector and no moving parts (MEMS elements travel less than 0.7 µm and have been tested by the military under severe conditions to withstand greater than 30,000 g).

Encoding with spatial light modulators

The DTS configuration mentioned above can be programmed via software to operate in various scanning modes. In a monochromator mode, the MEMS device filters one spectral region at a time and scans across the full spectral range to deliver a full spectrum. An NDIR mode (NDIR denotes nondispersive IR, a spectroscopic method that relies on a series of optical filters) enables the selection of a sequence of filter passbands equivalent to an NDIR filter wheel. A chemometric mode uses the analog control of individual pixels to implement optimum partial-least-squares weighting of multiple wavelengths; in this case, output is proportional to the concentration of target species. A digital-transform mode uses the programmability of the diffractive MEMS chip to implement an encoding scheme. This last method enables a full-spectrum measurement while maintaining 50% throughput (unlike the monochromator mode, whose throughput is inversely proportional to the pixel number).

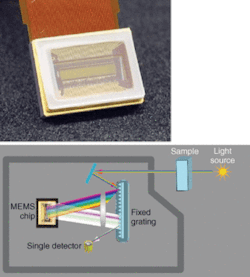

The digital-transform matrix in the latter method represents a time-sequenced (rows) set of spectral masks (columns represent pixels, which correspond to spectral ranges) created using the MEMS chip (see Fig. 2). Measuring the total power with the single detector for any individual spectral mask in the matrix yields a transform. When the transform is fully collected, it can easily be multiplied in firmware by the transform matrix to produce the full spectrum (see Fig. 3).

Stray light and dark current

Much work has been done in spectrometers to measure the desired optical signal while eliminating stray light and dark current. Stray light is defined as light that reaches the detector from undesired pathways such as internal reflections. Dark current is the background current measured with no light present. Dark current can be measured and subtracted from the signal but its value changes steeply with temperature. Stray light is difficult to measure and changes with the nature of the light spectrum passing through the sample. Because the sample is unknown, the stray light is not known.

A MEMS-based spectrometer overcomes these problems by using the digital-transform mode. The device measures every spectral region or pixel at “on” and “off” states to produce the transform. In the “on” state, the combined signal is measured (signal + dark current + stray light). In the “off” state, only dark current and stray light are measured. By subtracting the “off” measurement from the “on” measurement, DTS devices can deliver the net desired signal.

These DTS devices are compact and easily used for handheld applications. Because the MEMS engine is an electrostatic device, power consumption is low enough that DTS devices can use a standard USB port as both a power and communication interface. Devices have been constructed with a small footprint (3 × 4 × 5 in.) for a range of field and laboratory applications, as well as placement in online process-control systems.❏

REFERENCES

1. O. Solgaard et al., Optics Lett. 17, 688 (1992).

2. M. B. Sinclair et al., Applied Optics 36, 3342 (1997).

3. G. B. Hocker et al., Proc. Solid-State Sensor and Actuator Workshop, Hilton Head, SC, 89 (June 4-8, 2000).

4. M. B. Sinclair and K. B. Pfeifer, Materials Research Society Spring Meeting, San Francisco, CA, Symposium on Materials, Mechanisms and Systems for Chemical and Biological Detection and Remediation, April 14-15, 2004, paper Y4.1.

MIKE BUTLER is vice president of research and development, YARIV GELLER is director of business development, and MOULI RAMANI is vice president of business development and marketing at Polychromix, 30 Upton Drive, Wilmington, MA 01887; e-mail: [email protected]; www.polychromix.com.