NONCONTACT MEASUREMENT: Laser sees through car paint

If your 1998 car is already rusting, it may have been improperly painted, giving you a claim on your warranty. That's something auto makers would like to avoid, but spotting coats of paint that are too thin or too thick by a few thousandths of an inch can be difficult and time-consuming.

Making sure coats of paint are the correct thickness may become easier, thanks to a laser ultrasound system designed by Perceptron Corp. (Plymouth, MI), a process-control company, with a grant from the National Institute of Standards and Technology (NIST; Gaithersburg, MD) Advanced Technology Program. The system uses a pair of lasers to produce and detect ultrasonic waves in the wet paint as it is applied to cars, allowing manufacturers to catch and correct errors quickly. The device could replace the current inefficient process of testing with hand-held instruments after the paint has dried and after hundreds of other cars may have been similarly mispainted.

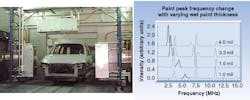

The system uses a Q-switched Nd:YAG laser emitting pulses at approximately 10 mJ, delivered through a fiber. The beam is passed through an optical parametric oscillator, which converts the wavelength to 1.57 µm, so that it is eye-safe. A second Nd:YAG laser emitting at its fundamental of 1064 nm is also directed at the car and then reflected to a Fabry-Perot interferometer. The interferometer records the Doppler shift in the reflected light caused by the ultrasonic waves passing through the paint. A frequency analysis of the signal shows how much vibration the first laser has caused (see figure).

"It's like a bell," said Jeffrey S. White, senior research scientist at Perceptron. "The thinner the bell, the higher the frequency. Well, for us, the higher the frequency we observe, the thinner the paint."

Traditional laser ultrasound is used to detect subsurface flaws in hard surfaces, such as concrete. The laser delivers as much power as possible to a tight spot to cause the surface to ablate. This is the opposite of what the Perceptron system does.

"We actually go way up in [spot] size and way down in energy. We don't ablate the paint," White said. "A lot of our work has been taking what you think of as laser ultrasonics and softening it down and fine-tuning it."

Cars are painted in four layers, and the system aims to measure the thickness of three of them. It examines 200 spots per vehicle, and each spot is shot three times and the measurements averaged. At plants that make 1000 vehicles a day—not an unusual number, said White—that's 1.8 million measurements a day. That process compares to using hand-held ultrasonic meters, with which manufactures make about 250 measurements per car on only two cars a day.

The laser is pumped by a flashlamp, with a useful lifetime of approximately 30 million shots. Such a system would require the lamp to be replaced roughly once month. White would eventually like to have a diode-pumped laser, and he would prefer to get 15 mJ/pulse, instead of the 10 in the current system.

An automotive plant can be a harsh environment, with temperature changes, vibrations, explosive vapors, and stray paint droplets. The system delivers and receives the beams through fiber, thus it can be placed away from the worst area and protected by a cabinet. And because the Doppler frequency measurements do not depend on the light intensity, a fair amount of paint splatter can cover the receiver and block some light without causing a problem.

The main advantage of the system, said White, is for process control, allowing workers to catch flaws in painting during application. They can stop the line and correct the problem before the car travels through a drying oven. Eventually, White said, it would be nice to build in a feedback mechanism, so the measurement system could stop the process instead of simply alerting humans.

Better process control would mean less repainting, saving money for manufacturers and consumers, and cutting down on the amount of waste paint, which is an environmental hazard. The economic possibilities are one of the criteria NIST used in awarding the grant.

"It's easily conceivable that we could save hundreds of millions of dollars a year," White said.

About the Author

Neil Savage

Associate Editor

Neil Savage was an associate editor for Laser Focus World from 1998 through 2000.