FLATNESS MEASUREMENT: Symmetry improves interferometer

Most commercial grazing-incidence interferometers in use are built around a very large right-angle prism that allows a circular area to be measured at a steep angle without much foreshortening. The prism must be made larger than the surface to be measured; thus, an instrument designed to measure 200-mm silicon wafers must include a high-quality prism of equal or greater clear aperture—a large chunk of glass indeed. Although diffractive grazing-incidence interferometers have been made that eliminate the prism, most such designs reflect the measurement beam from an object surface and combine it with a straight-through reference beam. The resulting wavefront inversion creates an additive sensitivity to errors in the interferometer optics and to air turbulence.

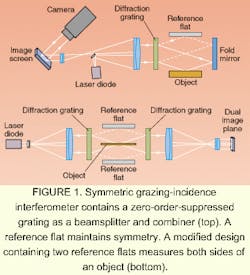

Peter Groot of Zygo Corp. (Middlefield, CT) has developed a simple diffractive grazing-incidence interferometer that incorporates a reference mirror and thus eliminates wavefront inversion (see Fig. 1 on p. 24). A fold mirror allows the same diffraction grating that splits the initial beam to recombine the reference and measurement beams; a tilted screen eliminates foreshortening. A modification of the design makes it possible to measure both sides of the same plane-parallel object; other changes make the instrument suitable for measuring cylindrical optics.

A 100-mW, 680-nm-emitting multiple-longitudinal-mode laser diode supplies light to the instrument, which has an equivalent measurement wavelength equal to the grating period. The interferometer is achromatic and has a symmetric equal-path geometry; thus, the light source can be both spatially and temporally low in coherence. Groot mentions the use of either an inexpensive multiple-transverse-mode laser diode or the combination of a laser diode and a rotating diffuser, the latter having the added benefit of eliminating speckle noise.

Using a standard Zygo 250-groove/mm diffraction grating, the experimental device currently measures surfaces up to 100 mm wide by 200 mm long and is capable of measuring 150 x 1500-mm surfaces, says Groot. With its 4-µm equivalent wavelength, the device produces fringes over several millimeters of surface height range. According to Groot, such a range makes possible uses in general industry such as the measurement of engine blocks, fuel-system components, machine tools, and pumps (see Fig. 2). Although there are no firm plans to commercialize the interferometer, Zygo is considering making a product if there is enough interest.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.