Wavelength References: Tunable laser, frequency combs, and integrated photonics forge an optical frequency synthesizer

Born out of research to meet the technical requirements of the Defense Advanced Research Projects Agency (DARPA) Direct On-Chip Digital Optical Synthesizer (DODOS) program, researchers at the University of Colorado, Boulder and the National Institute of Standards and Technology (NIST; also in Boulder, CO), the California Institute of Technology (Caltech; Pasadena, CA), École Polytechnique Federale de Lausanne (Lausanne, Switzerland), and Aurrion (Goleta, CA) have succeeded in developing the equivalent of a radio-frequency (RF) synthesizer that works in the optical domain.1 Their optical frequency synthesizer is able to generate precise optical frequencies on demand for applications in ultrafast science and metrology.

Microwave-to-optical conversion

To date, optical frequency synthesizers have been developed using mode-locked-laser frequency combs that provide the phase-coherent link between microwave and optical domains. A typical erbium-doped fiber comb system requires approximately 2 W of optical pump power and kilowatts of electrical power. But using silicon photonics (or integrated photonics) consisting of chip-based microresonator frequency combs—microcombs—pumped by continuous-wave (CW) lasers to enable parametric four-wave mixing, these microresonators can generate optical-comb frequencies with only milliwatts of external pump power and with very high pump conversion efficiency.

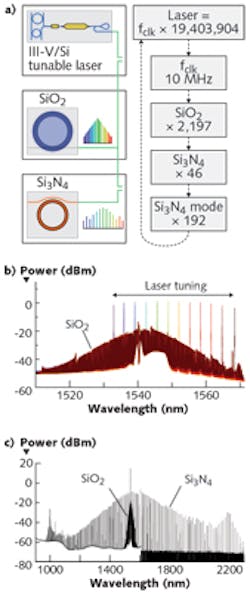

To fabricate the optical synthesizer, an external tunable laser feeds two dissipative Kerr soliton (DKS)-based microcombs consisting of a silicon nitride optical comb with octave bandwidth and 1 THz mode spacing, as well as a fused-silica comb with communications C-band-spanning bandwidth and 22 GHz mode spacing. Phase stabilization of the comb spacing and offset frequency performs phase-coherent multiplication of the 10 MHz RF clock to the optical domain, where a chip-scale III-V/silicon (Si) tunable laser disciplined to the microcombs creates the precision optical frequencies of the output, which can be tuned across a 32 nm (4 THz) window in the C-band region (see figure).

The optical frequency synthesizer can produce any wavelength within the C-band region at a relative wavelength precision of 7.7 × 10-15 and an absolute accuracy of 1.2 Hz. The linewidth and power of the output, derived from the III-V/Si laser, is approximately 300 kHz and >4 mW, respectively. To achieve broad wavelength operation, two Si-based ring resonators integrated with the III-V/Si laser cavity allow for Vernier-style tuning. The long-term frequency stability, derived from the user-chosen RF clock and transferred via the microcomb system, is demonstrated for >10 min. across multiple wavelengths.

“For the first time, accurate and precise optical frequencies fully traceable to international standards have been achieved using these low-power, miniature devices,” says Daryl Spencer, former physicist at NIST and lead author of the article. “Our team hopes to see these breakthrough devices become just as ubiquitous in optical applications as the microwave synthesizer is today.”

REFERENCE

1. D. T. Spencer et al., Nature, 557, 7703, 81–85 (Apr. 25, 2018).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.