Test & Measurement: Single-shot optical recording with sub-picosecond resolution spans record nanosecond lengths

RYAN MUIR and JOHN HEEBNER

The challenge of measuring fast events has resulted in a stream of innovation throughout history. Often when available measurement devices failed to meet the experimenter’s needs, a novel experimental method was developed to overcome the limitations of the time.

A famous example is of Wien, who in 1919 measured luminescence decay times by photographing the emission from a high-speed beam of particles. Through time-to-space mapping of the luminescing particle position along the trajectory of the beam, he achieved a staggering temporal resolution (for the time) fine enough to observe that the luminescence decayed exponentially with a 20 ns lifetime, allowing him to compare his results to Einstein’s prediction of excited-state lifetimes that had been proposed just two years earlier.

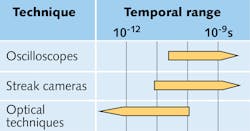

With the advent of electronics, oscilloscopes and photodiodes are now routinely capable of measuring events well below nanosecond resolution. However, these electronic instruments do not currently measure events below 10 ps resolution. From Walden’s observation that there is an engineering tradeoff between electronic bit depth and temporal resolution in analog-to-digital converters, this technique is projected to have extremely poor fidelity if it is extended to record single events with picosecond resolution.1 While this constraint may be circumvented with extensive signal averaging or other multiple measurements approaches, rare events and non-repetitive events cannot be observed with this technique. Techniques capable of measuring information in a single shot are often required.

Analog electronics and optical devices have been demonstrated to surpass analog-to-digital techniques for picosecond regime measurements (see Fig. 1). Streak cameras are commercially available to record temporal information onto a scientific camera with picosecond regime resolution, and single-shot autocorrelators deduce the pulse shape by using a nonlinear optical crystal to measure an ultrafast laser shot with itself.While powerful in their respective temporal domains, streak cameras suffer from space-charge effects that couple time resolution and dynamic range, and autocorrelators typically achieve limited record lengths. There is a general lack of available technologies that are easily scalable to long records with sub-picosecond resolution, and are simultaneously versatile in wavelength of operation.2

Since it is difficult to scale electronic methods to shorter resolutions, we instead aim to scale optical methods to longer records. Demonstrated optical recording methods that have achieved 1 ps resolution and long recording lengths rely on either time scaling to slow down the temporal information or, like Wien, perform time-to-space mapping so that fast events may be captured with a conventional camera.

These optical recording methods rely on mixing the information with a reference beam in a nonlinear optical crystal to scribe the information into either time (for stretching and scaling) or space (for imaging). Directly scaling up these techniques to records beyond what has already been demonstrated is difficult because of the weak nonlinear gain, small aperture, and stringent alignment and phase matching requirements of these materials.

Semiconductors as optics

Nonlinearities resulting from semiconductor-excited carrier-based changes to the refractive index are among the strongest nonlinear mechanisms, and can greatly exceed the nonlinear strength of wavemixing crystals. For example, an absorbing pump fluence of 100 mJ/cm2 can induce an index change of 0.02 in many III-V semiconductors such as gallium arsenide (GaAs), inducing a halfwave phase shift on a passing probe in only 30 μm. This effect can be used to create an optical modulator that optically switches the probe as controlled by the pump.

For comparison, to create a similar device based on a wavemixing process with the same fluence, 1 ps pulses would require at least two orders of magnitude more material thickness. With this stronger nonlinear gain, extremely large wafer apertures (and no requirement of phasematching), a single-shot optical recorder based on semiconductor nonlinearities could potentially scale to record lengths that are orders of magnitude longer than currently available optical recorders.

Despite the fact that semiconductor materials can be excited to the conduction band at sub-picosecond timescales, the majority of semiconductor materials decay back to their low-energy state at timescales of 0.1 ns to about 10 ns. This gives rise to an integrating behavior or fluence-dependent refractive index that is persistent, making these materials more challenging to use. Therefore, despite the relative abundance of cheap commercially available semiconductor wafers and thin films, they are uncommonly used as optical elements outside of optical detectors.

Semiconductor saturable mirror (SESAM) technology in modern ultrafast lasers directly confronts the long carrier lifetime problem by intentionally creating a high defect density in the semiconductor bulk material. These defects allow the carriers to quickly quench back to their non-conducting state several orders of magnitude faster, at the tradeoff of increased optical scattering and a distribution of carrier lifetimes throughout the material.

The Symmetric Mach-Zehnder Interferometer (SMZI) and Terahertz Optical Asymmetric Demultiplexer (TOAD) are both optical semiconductor switches.3 Both techniques mitigate the long integrating response by optical design instead of materials engineering—that is, they optically differentiate the long integrating response. Compared to the relatively niche set of activated semiconductor materials that have been well developed, this optical differentiation technique grants access to the full array of available semiconductor materials and films, allowing the ideal semiconductor to be chosen for the application.

Semiconductors for optical recorders

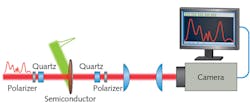

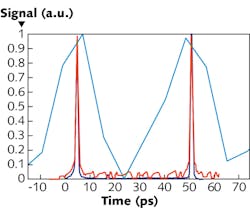

The Serrated Light Illumination for Deflection Encoded Recording (SLIDER) all-optical streak camera uses the long integrating response as a feature in its design.4 The pumped refractive index change is used to streak the light across a camera surface, resulting in a time-to-space mapping. The demonstrated single shot 50 ps record with 1 ps resolution cannot scale to longer records at this resolution because of free-carrier absorption attenuating the signal.Slanted Light Interrogation for Cross-Correlated Encoded Recording (SLICER), however, is a semiconductor-based optical recording technique that is scalable to very long records (see image at the top of this page).5, 6 Like the TOAD and SMZI optical switches, the semiconductor is placed within an interferometer to mitigate the sustained response (see Fig. 2). Because of the birefringent delay of the two optical input polarizations, the pump-induced phase shift causes the signal polarization to be transiently rotated at the counter-rotated birefringent output. This acts as a transient camera shutter when combined with a polarizer, with the shutter time determined by the pump duration and birefringent delay time. Finally, a time to space mapping is created by the oblique incidence angle of the pump beam across the wafer surface, which creates an ultrafast rolling shutter when imaged to the camera.

Scaling and versatility

Because of the high sensitivity of the SLICER mechanism, it can potentially be scaled to exceed a nanosecond at this resolution. Scaling up the sizes and apertures of all the optics is one path towards this goal, though imposing pulse front tilt on the pump from a grating could be used to keep the optics to a compact and manageable size. Demagnifying the image of a 150 mm grating with a near-grazing-incidence Littrow angle onto the semiconductor would create a 1 ns record. A large number of commercially available semiconductor options are available for signal and pump wavelengths spanning the far-infrared to the ultraviolet wavelength region.

The unused rows of pixels on the camera could be used in several ways. Additional pump stripes could capture multiple sub-records, or otherwise multiple channels of information. Upgrading the camera at the end of the SLICER device to an imaging spectrometer would upgrade the all-optical recorder to an all-optical spectrograph (to record wavelength vs. time), directly capturing information about the optical dispersion of the signal pulse without the need for any reconstruction algorithm. These enhancements, and many others not discussed here, demonstrate the versatility and power of the SLICER architecture.

ACKNOWLEDGEMENT

Lawrence Livermore National Laboratory is operated by Lawrence Livermore National Security, LLC, for the U.S. Department of Energy, National Nuclear Security Administration under Contract DE-AC52-07NA27344.

REFERENCES

1. R. H. Walden, IEEE J. Sel. Areas Commun., 17, 4, 539–550 (1999).

2. I. A. Walmsley and C. Dorrer, Adv. Opt. Photonics, 1, 2, 308–437 (2009).

3. P. Toliver et al., Opt. Commun., 175, 4, 365–373 (2000).

4. C. H. Sarantos and J. E. Heebner, Opt. Lett., 35, 9, 1389–1391 (2010).

5. R. Muir and J. Heebner, Opt. Lett., 42, 21, 4414–4417 (2017).

6. See https://ipo.llnl.gov/technologies/slicer.

Ryan Muir is a photonics engineer and John Heebner is the group leader for Ultrafast Optical & Electronic Systems, both at the Lawrence Livermore National Laboratory, Livermore, CA; e-mail: [email protected]; www.llnl.gov.