Although color is only one of the characteristics that make a commercial product an "eyecatcher," it ranks with shape as the most important. Marketers also know that, with the human eye's sensitivity to nuance and the psyche's desire for consistency, off-colors can connote a flawed product. A whole segment of industry has grown up around the use of color—not just the development of dyes and pigments, but also how they appear under different lighting conditions, lighting angles, and surface textures and treatments. Now, the National Institute of Standards and Technology (NIST; Gaithersburg, MD) has developed a color-calibration service for this industry based on a new reference instrument developed at NIST.

The colorimeter measures the spectral reflectance properties of nonfluorescent samples, from which color quantities are calculated. The instrument performs measurements at all possible combinations of illumination and viewing angles—important for accurate image rendering. In addition, the industry-standard measurement (at the so-called 0∞/45∞ geometry, in which illumination is at 0∞ and measurement at 45∞) is automated through the use of a sample wheel with a capacity of 20 samples.

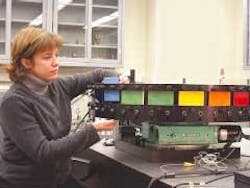

A sample is illuminated over a 12-mm2 area at normal incidence by a beam with a 5-nm bandwidth and linear polarization, as described by Maria Nadal, one of the NIST researchers (shown here loading color samples into the instrument). The illumination is provided by an incandescent or xenon-arc lamp, a 0.5-m double-grating monochromator, an aperture, reflective optics in a telecentric arrangement, and a polarizer. Light reflected from the sample is focused by a telecentric lens system onto a silicon photodiode.

The Optical Technology Division of NIST is offering a calibration service for the 0∞/45∞ industrial color standards. The service will be NIST's first for color measurement in many years, a response to needs articulated in recent reports of the Council for Optical Radiation Measurements (a group including NIST, other technical organizations, and industry representatives). The service complements ongoing services in reflectance, transmittance, and specular gloss. Industrial customers are expected to send samples (typically colored tiles) to NIST for measurement, then use these samples as standards to calibrate their own instruments. Users then typically convert a spectral reflectance measurement into the color coordinate system used by that particular industry. For more information, contact Maria Nadal at [email protected].

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.