Camera system redefines precision gunnery

Camera system redefines precision gunnery

Wendy Telford

The ability to accurately hit targets at great distances on a battlefield is a great tactical advantage for the military. To improve the firing accuracy of the M1A1 Abrams main battle tank, the US Army is using high-resolution digital cameras and a computer to make extremely accurate measurements during test firings. The goal is to obtain a computer correction factor that the fire-control system will use to accurately aim the main gun.

Several factors govern a projectile in flight: distance, gravitational force, projectile velocity, temperature, humidity, wind, and gun-barrel attitude. These variables and the computer correction factor are taken into account as the gunner aims the sight reticle at a target.

The computer correction factor takes into account "jump," which describes the unknown factors that contribute to a bullet trajectory. Jum¥must be empirically determined by experimentally tracking a projectile trajectory and then, starting from the point of impact, tracing a path back to the gun. The difference between the retraced path and muzzle can then be incorporated into the tank`s fire-control system as the jum¥factor. Consequently, jum¥is a measure of the compensation needed to land a projectile where desired after all other parameters have been factored in.

Camera system

Tests are conducted to establish the jump-compensation figure. The method for measuring the jum¥is based on criteria such as technical simplicity, practicality, and cost. Lido Engineering (Costa Mesa, CA), an electronic imaging company, designed an optical system that uses off-the-shelf, high-resolution cameras to provide extremely accurate measurements of the gun pointing direction.

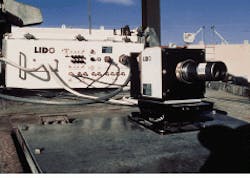

The optical system includes two Kodak Megaplus cameras (Model 1.4). One camera is mounted inside the tank at the gunner`s sight. The second camera is attached to the gun mount directly over the barrel to image the gun-pointing direction at the instant a round is fired (see photo). Taking parallax into account as well as other known factors, the difference between the two images gives the needed measurement.

The camera has to be ruggedized to withstand g forces and overpressures associated with firing rounds, as well as the heat and dust of the Yuma Proving Ground, AZ, test site. The ability of the second camera to take high-resolution images in the presence of these large perturbing factors is important. The imaging system has a 1000 ¥ 1000-pixel resolution. High resolution is necessary to meet the specification of 0.02-mil measurement accuracy--corresponding to an accuracy of 0.25 in. in one mile. An image grabber stores eight images in RAM, and software is used to calculate offsets and displacements from the digital images.

"We took the sensor and electronics of the Kodak Megaplus camera with little modification and designed a ruggedized package around it," Rick Clifford, president of Lido, explains. The camera has analog-to-digital converter capability, supports frame grabbers, produces the desired output, and is compact.

The camera has a charged-coupled-device array containing 1317 horizontal and 1035 vertical light-sensitive pixels. [A pixel is the smallest addressable element in an electronic display.] The 1.4 million pixels with 100% fill factor give the maximum sensitivity to an illuminated object.

Using computer-aided design, Lido engineers came u¥with a hardened camera casing that incorporates fins to radiate heat and special shock absorbers to handle the estimated 35 gs during the main gun recoil.

The entire system runs on a 486 PC with 16 Mbytes of memory and a magneto-optical drive. The images are momentarily stored in the image grabber before being dumped to a magneto-optical disk for permanent storage and retrieval.

Testing results

On the testing range, about 150 feet of cable separate the cameras and junction box from the computer and monitors. The 120-mm cannon is boresighted, which aligns the barrel and the gunner`s reticle. Prior to firing, the camera on the gunner`s optics images the target to give an exact point of the reticle aim. At the moment of firing, the main-gun camera automatically triggers, capturing the gun`s pointing direction again. The two high-resolution digital images, one from each camera, provide the data for an extremely accurate measurement of gun`s pointing direction.

The camera performed with no failures after more than 100 tests. The proving-ground facility will likely use the camera for other tests requiring imaging in a harsh environment. For example, high resolution lends itself to target-monitoring to measure impacts on targets.

WENDY TELFORD is a manager at the Motion Analysis Systems Division of Eastman Kodak Co., 11633 Sorrento Valley Road, San Diego, CA 92121.

Optical test system includes two cameras, one of which is bolted to the tank`s gun mount.