Simple dual-wavelength fiber laser setup measures large step heights

When the output of a laser is reflected by an external mirror back into the laser cavity, self-mixing interference (SMI) occurs within the laser-a phenomenon that can be used to measure the position of the external mirror to interferometrically high precision using a very simple setup. However, just as occurs with conventional single-wavelength interferometers, phase ambiguity for single-wavelength SMI limits the maximum measurement range to a distance of a half wavelength (λ/2). Phase ambiguity can be eliminated over a relatively large range by using two wavelengths instead of one. Researchers at Beijing Jiaotong University (Beijing, China) have developed a simple dual-wavelength fiber-laser setup for just this purpose that uses only a single ring cavity. The setup can measure a step height of up to 2 mm with a measurement standard deviation of 2.5 nm.

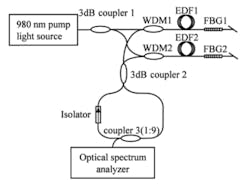

In the laser setup, a light source with a 980 nm wavelength and a 320 mW output is split into two beams, each of which is passed through a different wavelength division multiplexer (WDM), a length of erbium-doped fiber (EDF), and a fiber Bragg grating (FBG) that reflects light back at the Bragg wavelength. Each of the two FBGs has a slightly different Bragg wavelength (1549.952 nm for FBG1 and 1552.044 nm for FBG2). With the two lengths coupled together into a fiber ring cavity, an isolator in the ring forces the light to transmit in one direction in the ring to excite the fiber laser. The design ensures that, no matter how close the two wavelengths are to each other, no laser mode competition occurs between them, according to the researchers. A second circulator is added to the setup to measure distance unambiguously. Reference: L. Dong et al., Opt. Express (Sept. 12, 2016); http://dx.doi.org/10.1364/oe.24.021880.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.