INFRARED RADIOMETRY: Fiberoptic radiometer measures near room temperature

Researchers in the School of Physics and Astronomy at Tel-Aviv University (Tel-Aviv, Israel) have developed a noncontact IR multiband fiberoptic radiometer that is capable of measuring the real-time temperature of bodies near room temperature.1 Because direct contact with a sample is not always possible, and because prior similar methods can only measure very high-temperature objects (hundreds and thousands of degrees Celsius), this research has important implications in biology, electronics, and other fields.

Although IR radiometry allows measurement of the temperature of an object by measuring its emitted radiation, accurate measurements require knowledge of the sample emissivity-the ratio of the actual radiation emitted by a surface to the theoretical radiation predicted by Planck’s law. For many objects, emissivity is unknown, and is also a function of wavelength, temperature, and surface conditions. Fortunately, radiometers that measure in more than two spectral bands (multiband radiometers) are capable of simultaneously determining both the temperature and emissivity of a body.

Although multiband radiometers have been developed, their intense computational and high signal-to-noise-ratio (S/N) requirements have only allowed for measurements at high temperature. To overcome these limitations, the researchers used special optical fibers and multiband filters to improve the S/N of their measurements.

Silver halide fiber

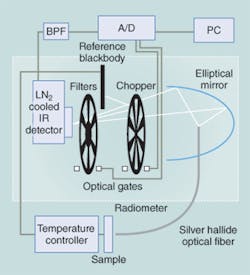

For fiberoptic radiometers (important in medical or industrial applications for which a clear line-of-sight to the object is not often available), the spatial resolution of the measurement is determined by the cross-sectional area of the fiber. Using a special silver halide fiber produced by their group, a mercury cadmium telluride liquid-nitrogen cooled detector, and a series of six narrowband IR filters, the researchers constructed a multiband fiberoptic radiometer (see figure). Radiation from the sample was transmitted by the core-only optical fiber-which had very high mid-IR transmission and a diameter of 700 mm-and focused by an ellipsoidal mirror onto the detector after passing through the filter wheel rotating at 1 Hz. A reference blackbody at 24°C was used to reduce drift caused by changes in the radiometer temperature, while a 16-bit analog-to-digital converter at 40 kHz was used to digitize the voltage signal from the detector, reducing the time to obtain a high-S/N signal through each filter to 80 ms.

A system of six nonlinear mathematical equations (one for each filter) with up to five unknown variables (including temperature and emissivity of the measured sample) solved the equations in 1 s for each 1-s rotation of the filter wheel, for a total online computation time of 2 s.

The accuracy of the radiometer was validated against contact measurements using objects with known emissivity in the range of 0.70 to 0.90 and average body temperatures between 50°C and 90°C in a room at 20°C. During the measurements, the sample temperature was varied to demonstrate how the system performed when tracking temperature in real time. The resulting accuracy of the measurements made by the multiband fiberoptic radiometer was approximately 1°C for temperature and 0.03 for emissivity.

“Recently, we have extended the capabilities of the constructed system by incorporating a core-clad IR silver halide fiber (developed in our group by Shaul Shalem), instead of a core-only one,” says researcher Igor Uman. “This increased the accuracy of the measured temperature. In addition, core-clad fibers allow performing small spot measurements with the radiometer. The obtained results will be submitted for publication in the near future.”

REFERENCE

1. I. Uman and A. Katzir, Optics Lett. 31(3) 326 (Feb. 1, 2006).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.