Spectroscopy: Binary coded aperture trumps slit for signal

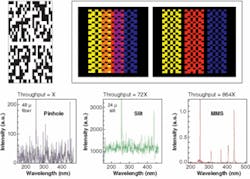

Users of conventional slit-based dispersive spectrometers face a dilemma. A spectrometer designed with narrow slits for a high resolution has a low optical signal; widening the slit to increase the signal lowers the resolution. For some applications, the result is a compromise instrument that combines a barely acceptable resolution with a low signal-to-noise ratio. Engineers at Centice Corp. (Durham, NC) have produced an alternative that sidesteps this problem by replacing the slit with a binary coded aperture that, when used with computer processing, boosts light throughput by a factor of 12 over a slit-based system. Dubbed multimodal multiplex spectroscopy (MMS) by Centice, the approach was debuted at this year’s Pittcon conference (March 12-17; Orlando, FL).

The coded aperture consists of many adjacent narrow, slit-width stripes, each of which has a different binary one-dimensional (1-D) spatial coding. Placed in an otherwise conventional dispersive spectrometer, the coded aperture results in the spreading of light of each wavelength across a broad swath at the detector plane where the aperture is imaged.

Algorithm a key part

In a conventional instrument, this spreading would degrade resolution, but in the MMS version, the binary coding allows a 2-D image sensor combined with an image-processing algorithm to separate each wavelength to the resolution that would be attained by a slit the width of an individual coded stripe. For an MMS aperture with 24 stripes, the increase in light throughput over a single slit is 12 (the binary coding passes, on average, half the light). The advantage of MMS over spectrometers that use an optical fiber (which is a pinhole source) instead of a slit is much greater yet-for example, a factor of 864, based on one calculation for a typical instrument with a fiber input.

The technology was originally developed at Duke University under grants from the National Institutes of Health and from DARPA for tissue spectroscopy and spectroscopic imaging, explained Mike Fuller, Centice’s director of product marketing, at Pittcon. As a spinout formed in 2004, Centice is the exclusive licensee and, in fact, revealed the technology to a certain extent before its official debut; at Photonics West 2006 (Jan. 21-26; San Jose, CA), Centice announced partnerships with Newport (Irvine, CA) and Ocean Optics (Dunedin, FL) under which its partners will launch spectrometers incorporating the MMS technology.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.