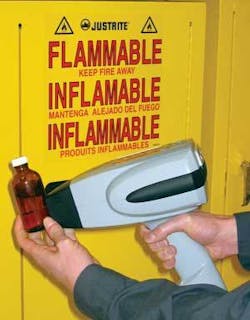

SPECTROMETERS: Handheld analyzer detects many substances

At this year’s Pittcon conference (March 12-17; Orlando, FL), Polychromix (Wilmington, MA) launched a miniature near-infrared (NIR) spectrometer that is held like a pistol and looks very much like a police radar gun. In fact, the instrument, which the company claims is the first handheld NIR digital-transform spectrometer (DTS) analyzer, may one day be used by police to identify illicit drugs or hazardous substances.

The device forgoes the high-cost components of conventional broad-bandwidth miniature NIR spectrometers, which are based on indium gallium arsenide detector arrays. Instead, it is based on a MEMS (microelectromechanical systems) chip and a single detector. A fixed diffraction grating creates a spectrum from the incoming light to be analyzed; the spectrum is projected onto the MEMS chip, which selects and modulates the relevant wavelength or wavelengths. The selected wavelengths are recombined by the same grating and imaged onto the detector. The resulting digitized signal is then processed, for example, by applying a Hadamard or other transform.

The instrument contains a light source, reflectance probe, computer, and display, and is battery-operated. The optomechanical subsystem fits in a 4.2 × 3.3 × 5.7 in. package. The device has a spectral range of 900 to 1700 nm and a digital resolution of 0.8 nm (arising from the 100-pixel length of the MEMS device); the company is working on a version with a 1700 to 2500 nm range. The optical resolution is 12 nm.

The absorption bands of many common molecules lie in the 1800 to 2500 nm range, with the shorter-wavelength end containing primarily third-, second-, and first-overtone bands, and the longer-wavelength end containing combination bands. These include absorption bands of many hydrocarbons, as well as other organic substances.

For example, ethyl alcohol has a well-defined spectral shape in the NIR. Measuring the absorption spectrum of wine or beer as it is being made, then subtracting out the water spectrum, allows a vintner or brewer to estimate alcohol content of the mix. Analyses such as subtracting one spectrum from another can all be carried out on the computer in the handheld instrument. Other industrial uses include identifying hydrocarbon distillation fractions in the petrochemical industry, and solvent mixtures in general. Solid plastics, even many polymers fully formulated with fillers, can be identified, usually in reflectance, but also in transmission for transparent plastics. Fats and oils in meat and other foods can be identified through clear packaging material.

The small DTS analyzer is aimed at the world beyond the laboratory, said Mouli Ramani, vice president of business development for Polychromix, who demonstrated the device’s point-and-click identification of sugar types at Pittcon. He noted that “white powder” identification by law enforcement could be just as quick.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.