Integrated food-testing spectrometer is smaller than a sugar cube

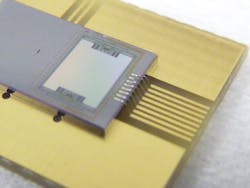

Dresden, Germany--A spectrometer only 2.1 cm3 in volume created by a group at the Fraunhofer Institute for Photonic Microsystems (IPMS) is intended for testing food items for ripeness, water content, and other qualities. The researchers say the spectrometer could one day be installed in smartphones.

If that were the case, all one would need to do is hold a smartphone near the product in question, activate the corresponding app, choose the food type from the menu—for example, “pear”—and the device would make a recommendation: for example, "the fructose content of the pear is high, so buy it." The small near-IR spectrometer can measure the amount of water, sugar, starch, fat and protein present in a product. The instrument can see several centimeters below the outer surface of a food item—which means that it can detect, for instance, whether the core of an apple is already rotting. Thin packaging film is no problem for the device as the device takes measurements straight through it, says IPMS.

The spectrometer's 2.1 cm3 volume is about 350 times smaller than commercially available counterparts, which are around 350 times larger; in addition, says IPMS, the devices are inexpensive to make and suitable for mass production. “We expect spectrometers to develop in the same way that digital cameras did,” says Heinrich Grüger, who manages the relevant business unit at IPMS. “A camera that cost 500 euros ten years ago is far less capable than the ones you get virtually for free today in your cell phone.”

The IMPS researchers fabricate the spectrometer's individual gratings and optical gaps directly on silicon wafers. Each patterned silicon wafer is large enough to hold the components of several hundred spectrometers, which means that hundreds of near-IR systems can be produced in one go. The scientists stack the wafers containing the integrated components on top of the wafers bearing the optical components, align and bind the wafers, and divide them to form individual spectrometers.

At the Sensor+Test trade show being held in Nuremberg from May 22 to 24, the IPMS research scientists will be exhibiting a prototype of the spectrometer (in Hall 12, Booth 202). The device could be ready for market launch in three to five years, according to IPMS.

The researchers are also working on creating a corresponding infrastructure. “We are developing intelligent algorithms that analyze the recorded spectrums immediately, compare them with the requirements, and then advise the consumer whether or not to buy the item, says Grüger. "This advice is based solely on quality features such as ripeness and water content. The system cannot carry out a microbiological or toxicological analysis.”

Other potential applications exist also: The device can also detect forgeries, for example, and can verify whether a product is made of high-quality original materials or whether it is a cheap fake. It can also reveal whether parts of a vehicle’s body have been repainted, as well as test the contents of drugs and cosmetic creams.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.