University of Cambridge researchers develop printable lasers

Cambridge, England--Scientists at the University of Cambridge have designed a process to “print” a type of organic laser on any surface, using a custom inkjet printing system. The process involves developing lasers based on chiral nematic liquid crystals (LCs), similar to the materials used in flat-panel LCD displays. These photonic materials can, under the right conditions, be stimulated to produce laser emissions.

If aligned properly, the helix-shaped structure of the LC molecules can act as an optically resonant cavity. After adding a fluorescent dye, the cavity can then be optically excited to produce laser light. Until now, high quality LC lasers have been produced by filling a thin layer of LC material between two glass plates spaced 10 microns apart. The glass must be covered with a specially-prepared polymer coating to align the LC molecules. The research is reported in the journal “Soft Matter.”

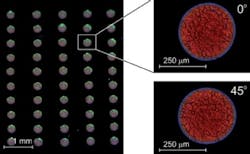

Unfortunately the process is still a complex one—it requires a cleanroom environment and involves multiple, intricate production steps. Furthermore, the range of substrates available is typically restricted to glass or silicon. The researchers devised a way to align the LC molecules and produce high resolution multicolor laser arrays in one step by printing them. They printed hundreds of small dots of LC materials on to a substrate covered with a wet polymer solution layer. As the polymer solution dried, the chemical interaction and mechanical stress caused the LC molecules to align and change the printed dots into individual lasers.

The researchers believe this process can form lasers on virtually any surface, rigid or flexible, and can potentially be applied using existing printing and publishing equipment similar to the ones used to print magazines. The process has been developed initially to produce compact, tunable laser sources and high-resolution laser displays. However, it can also be used to print fluorescence-tag-based “lab-on-a-chip” arrays used in biology and medicine.

A UK patent application to protect the invention has now been filed with the help of Cambridge Enterprise, a subsidiary of the University of Cambridge which is responsible for commercialization arrangements for University discoveries.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.