Field-induced polymer electroluminescent (FIPEL) lights don’t flicker, shatter, or burn out

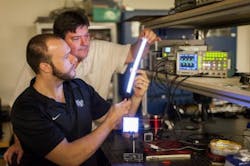

Winston-Salem, NC--Scientists at Wake Forest University have developed a flicker-free, shatterproof alternative to the standard fluorescent tube for large-scale lighting: field-induced polymer electroluminescent (FIPEL) technology. The researchers says that FIPEL gives off soft white light—not the sometimes yellowish color from fluorescents or the bluish tinge from many LED lamps.

The FIPEL lamp relies on a nano-engineered polymer matrix to convert electrical charge into light. The research supporting the technology is described in a study appearing online in advance of publication in the peer-reviewed journal Organic Electronics.

The device is made of three layers of moldable white-emitting polymer blended with a small amount of multiwalled carbon nanotubes (MWNTs) that glow when stimulated by an AC field to create bright white light similar to the sunlight human eyes prefer. However, it can be made in any color and any shape, from 2 × 4-foot sheets to replace office lighting, to a bulb with Edison sockets to fit household lamps and light fixtures.

This new lighting solution is at least twice as efficient as compact fluorescent (CFL) bulbs and on par with LEDs, say the researchers, noting that FIPEL bulbs don't shatter and contaminate the surroundings with mercury like CFLs.

Beyond office and home lighting, scientist David Carroll of Wake Forest sees potential uses for large display lighting, from store marquees to signs on buses and subway cars. FIPELs also are long-lasting; Carroll says he has one that has worked for about a decade.

Wake Forest is working with a company to manufacture the technology and plans to have it ready for consumers as early as next year.

For more info, see: http://www.sciencedirect.com/science/article/pii/S1566119912004831

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.