Moorestown, NJ--The last of the 18 beryllium mirror segments that make up the primary mirror for the James Webb Space Telescope (JWST), along with three spares, has been high-reflection gold-coated by Quantum Coating Inc. (QCI). The precision process took time: the first segment was finished in June, 2010.

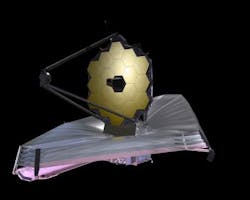

The 1.5 m segments will form a hexagonal array. The JWST is optimized for the IR—thus the gold coating. The telescope will provide images of the first galaxies ever formed, as well as find planets around distant stars. It is a joint project of NASA, the European Space Agency, and the Canadian Space Agency. The JWST program is in some trouble, having been canceled by the U.S. House of representatives, but many (including SPIE) hope the program can be rescued.

Mirror manufacturing began eight years ago with beryllium blanks. Several of the smaller mirrors in the telescope, the tertiary mirror and the fine steering mirror, were coated in 2010. The secondary mirror was finished earlier this year.

QCI constructed a new coating facility and clean room to coat the large mirror segments. QCI developed the 120-nm-thick gold coating for high performance as far as uniformity, cryogenic cycling, durability, stress, and reflectance in a two-year effort prior to coating the first flight mirror.

"We faced many technical challenges on the Webb mirror coating program,” said Ian Stevenson, director of coating at Quantum Coating. “One of the most daunting was that all flight hardware runs had to be executed without a single failure."

The mirror segments were recently shipped to Ball Aerospace (Boulder, CO) where actuators are attached. From there, the segments travel to the X-ray and Calibration Facility at NASA's Marshall Space Flight Center (Huntsville, AL) to undergo a final test when they will be chilled to -240 degrees Celsius. The last batch of six flight mirrors should complete the test by the end of this year.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.