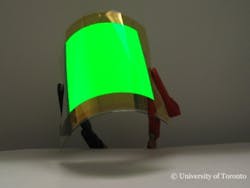

U. of Toronto scientists create world's most efficient flexible OLEDs on plastic

Toronto, ON--A group at the University of Toronto has created a thin-film enhancement to organic LEDs (OLEDs) that boosts their efficiency without requiring a high-refractive-index substrate.1 This means plastic can be used instead of glass; the innovation allowed the group to create the world’s most efficient OLED on plastic. The external quantum efficiency reached 63% for green, and remained as high as 60% at greater than 10,000 cd m–2.

Conventional OLEDs require the use of heavy-metal-doped glass with a refractive index of at least 1.8 to efficiently couple light out of the device. However, glass does not make for a truly flexible device (a bit of a bend, maybe, but not more). The U. of Toronto invention allows for the use of lightweight and flexible plastic substrates having an index of less than 1.6. The thin-film light-outcoupling layer includes films of tantalum pentoxide (Ta2O5; optical outcoupling), gold (electrical conduction), and molybdenum trioxide (MoO3; hole conduction). The researchers have fabricated high-efficiency phosphorescent OLEDs using the design. The performance of the device is comparable with the best glass-based OLEDs, while providing the benefits offered by using plastic.

"For years, the biggest excitement behind OLED technologies has been the potential to effectively produce them on flexible plastic," said materials science and engineering Professor Zheng-Hong Lu. "This discovery unlocks the full potential of OLEDs, leading the way to energy-efficient, flexible and impact-resistant displays."

REFERENCE:

1. Z. B. Wang et al., Nature Photonics, published online 30 October 2011; doi:10.1038/nphoton.2011.259

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.