When combined with yellow phosphors, indium gallium nitride (InGaN) LEDs have become the star of the lighting industry, producing white light at high efficiencies and long lifetimes. But InGaN itself has a bandgap that can be varied from the UV (3.4 eV) to the near-IR (0.7 eV) depending on the proportion of In, which means that, at least in theory, red, green, and blue InGaN LEDs could be fabricated and combined to create white LED without the use of phosphors. While long-wavelength (yellow) InGaN LEDs have been fabricated, they have been grown on expensive substrates with alternate, hard-to-create crystal planes at higher cost.

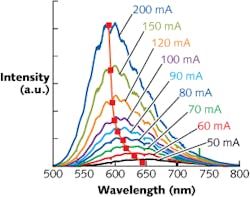

Researchers at National Chiao Tung University and Academia Sinica, both in Taiwan, are solving this problem by taking ordinary InGaN substrates (with the wrong crystal orientation for long-wavelength LEDs) and growing nanopyramids on them, which naturally form nanocrystal planes with the right orientation for long-wavelength, electrically driven InGaN LEDs—in this case, producing green, “olivine” (greenish-yellow), and amber (orangish-yellow) light. The pyramids are on the order of 400 nm in size and tend to have triangular bases. The experimental internal quantum efficiencies for the green, olivine, and amber LEDs were 30%, 25%, and 21%, respectively; this graph of emission spectrum as a function of driver current for the amber LED shows the typical shift to longer wavelengths at lower current, reaching a true red at low-enough values. Contact Yuh-Jen Cheng at [email protected].

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.