Jefferson Lab's FEL gets down to business

H. Frederick Dylla

As Thomas Jefferson once said, "Every science is auxiliary to every other." Now researchers at the US Department of Energy's Thomas Jefferson National Accelerator Facility are busy proving it with the world's most powerful tunable laser. Since coming on line in 1999 and reaching 1.72 kW at 3.1 µm, Jefferson Lab's kilowatt-scale free-electron laser (FEL) has been enabling research with applications in applied and basic science fields ranging from materials science and chemistry to nanotechnology and biology.1 Plans are now in the works to upgrade the FEL to extend its operation in the infrared to the 10-kW level and to provide kilowatt operation in the visible and ultraviolet (UV) regions down to 300 nm.

FEL operations

Jefferson Lab's FEL, built with superconducting electron-accelerating technology originally developed for nuclear physics research, delivers a close-to-diffraction-limited beam of infrared light at 3 to 7 µm in a continuous train of subpicosecond (~700 fs) pulses at a repetition rate of 75 MHz. Table-top femtosecond-class lasers have shown the pulse length to be nearly optimal for the efficient deposition of laser energy into materials at the surface. The laser also delivers 300 W at 1 to 3 µm, 100 W in the green, and 10 W in the UV by harmonic generation.

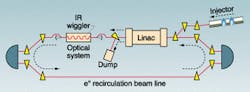

Experiments take place in 10,000 square feet of laboratory space on the FEL User Facility's second floor. On the floor below, the FEL is roughly the shape of a racetrack about 50 m long (see Fig. 1). Its operation begins with a conventional frequency-doubled Nd:YLF (yttrium lithium fluoride) laser that frees electrons by ejecting them off a 350 kV direct current photocathode. After the electrons transit a short length of highly efficient superconducting radio-frequency (SRF) accelerator, they are injected into the longer SRF "driver" accelerator to reach 48 MeV. Then a "wiggler"two lines of opposing magnetsstimulates radiation from them (see Fig. 2). Amplification takes place in an optical cavity with a high-reflection dielectric mirror and a 90% reflecting output mirror. Resulting laser light is directed upstairs for experiments.

Since production of the light requires only 1% of the electron beam's energy, Jefferson Lab pioneered the recycling technique of "energy recovery" to multiply the already high efficiency of SRF acceleration. After exiting the wiggler, the electron beam returns along the back leg of the racetrack, re-enters the driver accelerator 180

Long-term goals

Jefferson Lab's long-term research and development intent is to continue developing SRF-driven, energy-recovering FELs as a practical laser technology offering high average power, broad tunability, and unique time structure. This combination makes FELs useful for materials processing and related basic science studies. Such FELs can potentially overcome the cost, capacity, wavelength, and pulse-length constraints of conventional lasers.2

The FEL has numerous demonstrated applications, including: pulsed laser ablation and deposition, laser nitriding, synthesizing carbon nanotubes, and micromachining.

Pulsed laser ablation and deposition is a key potential applied-science application for manufacturing large-area films. The FEL's ultrafast pulses offer a low ablation threshold, substantially lessened target damage, and particulate elimination. High repetition rate equates to a high deposition rate, and may mean greater control over ablation and growth dynamics. Wavelength tunability results in enhanced ablation and deposition with resonant absorption, such as in polymers, using specific resonances to control growth processes. About a dozen materialsranging from metals to polyimide to siliconhave been ablated, and about half of them have been deposited as well. The work was performed at 3.1 µm, with deposition rates 10 to 100 times higher than those observed with excimer lasers.

Another industrial application of the FEL is laser nitriding, a method of modifying the properties of metals to obtain a harder surface with better corrosion resistance and the ability to hold higher standoff voltages (see Fig. 3). Similar work has been conducted with plasma immersion, ion-beam processing, and conventional lasers. The Jefferson Lab FEL was successfully used to produce high-quality nitride films on iron, titanium, and silicon. After the process is optimized, the high average power of the FEL will offer commercially attractive production rates.

Carbon nanotube structures present a range of production challenges that might be circumvented or better understood by use of the Jefferson Lab FEL's repetition rate, wavelength tuning, and power. Studies are under way to determine how the structures are formed and discover optimum conditions for making them with tailored properties, as well as to learn more about real-time process monitoring and control. Nanotubes have been prominent in the news because of their potential applications. Besides imperviousness to extreme heat, they have properties potentially useful for high-strength composites and nanoelectronics. Preliminary results from the FEL are promising. It has synthesized single-wall carbon nanotubes with 6-µm light at 400- to 600-W average power (see Fig. 4). The bundles have smaller diameters than nanotubes produced by direct current arc or by table-top pulsed laser vaporization (PLV), with production rates measured in milligrams per minute rather than milligrams per hour. Further FEL work is planned to understand and optimize PLV processes and to create unique materials, including silicon nanowires, germanium nanotubes, and gallium arsenide nanostructures.

Micromachining is one of the most attractive FEL applications. DuPont (Wilmington, DE) and NASA (Langley Research Center; Hampton, VA) are interested in micromachined polyimide, which is applied widely in printed wiring board dielectric layers and ink-jet printer heads and might prove useful for space sails. Siemens (Munich, Germany) is using the FEL for studies of micromachined metals for automotive engine applications. The Aerospace Corp. (El Segundo, CA) is studying micromachined glasses and ceramicsmaterials made much easier to cut and shape when light is the tooland is using Jefferson Lab's tunability and power to study the fabrication of true three-dimensional microstructures. With nano-scale engineering of key features, some satellites could be reduced to the size of baseballs or smaller.

Upgrade/enhancement plans

In addition to extending the FEL's operation in the infrared to 10 kW and providing kilowatt operation in the visible and UV down to 300 nm, Jefferson Lab is pursuing generation of terahertz radiation (T-rays) and commissioning a compact synchrotron.

Underpinning the FEL's applications is a basic research program that strives to understand both linear and nonlinear phenomena in materials as diverse as proteins and metals. Linear dynamics using pump-probe techniques has been applied to amide-I absorption at 5 to 8 mm in proteins, and to hydrogen defects in silicon at 3 mm.3, 4 Research is planned to investigate nonlinear interactions in metals and gases, and to study phenomena that determine ablation ratessuch as multiphoton absorption. Subpicosecond time structure is critical in defining these fast, dynamic processes.

A significant enhancement to the facility is expected with the commissioning of a compact synchrotron as a broadband source of light from infrared to x-rays. Synchrotron radiation pulses will be synchronized with those from the FEL. The laser itself, with its SRF driver accelerator, has begun producing nonlaser light of two kinds: ultrafast x-ray pulses, and T-rays.

Subpicosecond x-ray pulses are generated within the FEL by Thomson scattering of the infrared light with the electrons. The pulses are extracted in coincidence with the infrared light pulses, and may lead to pump-probe studies based on two distinct inputs. In solid-state physics and materials science, potential pump-probe applications include temporal dynamics of condensed-matter phase transitions, the ultrafast time-resolved monitoring of structural changes in materials, and heat propagation at submicron dimensions. In biology and chemistry, the capability could be applied to studies of short-range order changes in chemical reactions. In accelerator physics, it could be applied to the development of beam diagnostics for next-generation light sources.

In the first attempt to generate terahertz pulsed radiation with this FEL, Jefferson Lab's FEL has demonstrated microwatt-scale T-rays by the excitation of indium arsenide (InAs) with 10-W, 1-mm light (at the third harmonic of 3 mm). A strong saturation effect limited the emission efficiency to 10-7. At higher power, milliwatt-scale T-ray production appears feasible. The laboratory plans to generate watt-scale T-rays by extracting synchrotron radiation from a bending magnet in the electron beam transport system of the high-current (5 mA) FEL driver accelerator. T-rays hold intrinsic interest for basic science, but applications are expected as well in information technology, geological and medical imaging, and nondestructive testing of materialsdemonstrating how multiple scientific disciplines enable and profit from Jefferson Lab's light-source technologies.

REFERENCES

- G. R. Neil et al., Phys. Rev. Lett., 84, 662 (2000).

- M. J. Kelley, SPIE, 3888, 598 (2000).

- R. Austin, Phys. Rev. Lett., 84, 5435 (2000).

- M. Budde et al., Phy. Rev. Lett., 85, 1452 (2000).

ACKNOWLEDGMENTS

The author would like to acknowledge the contributions of the members of the Jefferson Lab FEL team. Crucial to Jefferson Lab's FEL effort is the support of the US Department of Energy, the Office of Naval Research, the Commonwealth of Virginia, and the industry and university partners in the Laser Processing Consortium.

H. FREDERICK DYLLA is the FEL program manager at the US Department of Energy's Thomas Jefferson National Accelerator Facility, 12000 Jefferson Avenue, Newport News, VA, 23606; e-mail: [email protected].