Digital thin-film memory devices store data in color

Researchers at the Nanoelectronics Laboratory (Nanolab) at the University of Cincinnati (Cincinnati, OH) have developed a nontraditional approach to increasing the density of optical memory. According to lab founder and director Andrew Steckl and research assistant Robert C-J Chi, because the technique relies on a broadband light source instead of a laser, users easily can discriminate among various color levels in the reflected image.

The device built by the researchers, which is called digital thin-film (DTF) color optical memory, reads data from arrays of bit patterns that have been micromilled on silicon-dioxide thin films.

So far, the scientists have built DTF optical memory structures with pixel-to-pixel pitch of 700 nm and 16 physical levels or four bits/pixel, which translates to an equivalent data storage density exceeding 5 Gbit/in.2. They believe storage capacity may someday reach terabit levels.

Like CD ROM technology, the DTF readout process, which uses a charged-coupled device (CCD) array to read light reflected off the patterned surface, relies on the interference of light, but there the similarities end. With CD ROMs, the data storage and retrieval process involves reading the interference pattern of single-wavelength laser light reflected off pits in a surface, as well as the area laterally surrounding them. The resulting constructive or destructive interference is then interpreted as either a binary 1 or 0. In the DTF structure, the interference process occurs vertically between two interfaces of the dielectric thin film, and the reflected output is the superposition of many interference patterns of different wavelengths. The color corresponding to each pixel location is a function of film thickness, incident light spectral profile, and spectral responsivity of the detector. According to the University of Cincinnati scientists, the DTF structures thus can offer multiple memory-bit storage in the third dimension, while the CD ROM structure is basically limited to only two states or one bit per physical location.

To prove the multicolor optical memory concept, the scientists used focused ion-beam micromilling to fabricate arrays of pixel patterns on 800-nm oxide thin films grown on silicon substrates. This technique etched the surface using gallium ions (Ga+) accelerated to an energy of 30 keV, with milling rates reaching up to 310 µm/s. Pixel depth adjustments were made by adjusting the ion dosage. The resulting data locations or pixels varied in size from roughly 0.5 to 2 µm and had as many as 256 depth levels (or 8 bits/pixel) ranging from zero to nearly 800 nm.

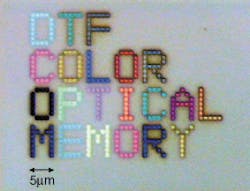

A demonstration of the effect is shown in the figure, which illustrates color capability of the reflected-light image of a fabricated DTF memory structure. The image, which was captured using an objective lens (100X and NA of 0.9) and a charge-coupled-device (CCD) camera, has a pixel-to-pixel pitch of roughly 1 µm, with 16 film thickness levels or four-bit color depth. In addition to increases in bit density, the DTF structure creates "microcolor" digital images permanently embedded in the memory device. This property can result in novel approaches to data security.

According to the project researchers, the bit density capacity of the DTF optical memory device depends on several factors. Keys to successful processing include the ability of the ion-beam milling process to pattern nanometer-scale regions with high precision in all three dimensions and the capability of the readout system to detect optical signals from these pixels. Both areas still require further investigation.

REFERENCE

- C. J. Chi and A. J. Steckl, Appl. Phys. Lett. 78, p. 255 ( Jan. 2001).

About the Author

Paula Noaker Powell

Senior Editor, Laser Focus World

Paula Noaker Powell was a senior editor for Laser Focus World.