Researchers in the biological research center of the Hungarian Academy of Sciences (Szeged, Hungary) have used laser light to create, position and drive micron-scale pinwheels and have even fabricated several of the spinning light-engines into a propeller-driven gear train.

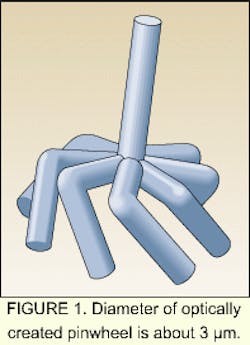

Each pinwheel was made using a focused laser beam to polymerize an ultraviolet-light-sensitive optical adhesive. The adhesive (NOA 63: Norland Products; Cranbury, NJ) was polymerized using the 514-nm output of an argon-ion laser focused through an objective lens so as to initiate the two-photon excitation necessary for a polymerization-line thickness on the order of 0.5 µm under about 20 mW of laser irradiation (see Fig. 1). The pinwheel shape of the polymerized material was obtained by moving the sample on a three-axis piezo stage during the laser polymerization process. Several hundred pinwheels were fabricated in this manner in a batch of optical adhesive, which was then placed in an acetone solution to dissolve the material that did not polymerize and to provide a medium for subsequent rotation experiments.

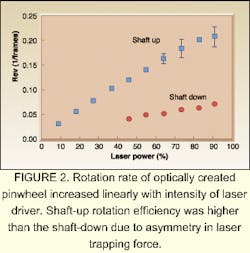

The resulting pinwheels were held in place and spun using a laser tweezer system (Cell Robotics; Albuquerque, NM) illuminated by a 994-nm infrared diode laser (SDL; San Jose, CA) and focused through a microscope (Axiovert 135: Carl Zeiss; Thornwood, NY). The system provided a trapping intensity on the order of 20 mW, and the angular speed of the rotating pinwheels depended upon both the orientation of the pinwheels in the solution and the intensity of the laser illumination (see Fig. 2). The angular speed was neither dependent upon the polarization state of the trapping light nor upon any other characteristic of angular momentum within the light beam, but was due entirely to that helical shape of the trapped pinwheel.The pinwheels were observed to occupy one of two stable orientations within the acetone solution: either shaft-up or shaft-down with respect to the incident trapping laser-beam. The rotation efficiency turned out to be much higher for pinwheels in the shaft-up orientation due to an asymmetry in the laser trapping force, according to the researchers. "The total force acting on the trapped body consists of two components: a gradient force pulling the body into the center of the beam waist and a scattering force pushing the body away from the light source," they wrote.1 The researchers also used their apparatus to fabricate three pinwheels simultaneously that were connected together like gears in a transmission, such that one of the pinwheels rotated under light stimulation similar to a propeller and drove the other two as if they were cogwheels.

REFERENCE

- P. Galajda and P. Ormos, Appl. Phys. Lett. 78, 249 (January 8, 2001)

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.