Researchers at the University of Michigan (Ann Arbor, MI) are combining Raman microspectroscopy with mechanical testing to gain insight into how chemical variations in bones influence their response to fatigue and stress, and hence the risk of fracture.

"An important aspect of the analysis is showing that the variation in chemical composition between normal and damaged bone tissue is much greater than the small chemical variations usually seen in normal bone tissue," said project leader David Kohn. "We already know that age and disease affect a bone's ability to repair itself. For the first time we're now learning how chemical changes can impact the behavior of a bone."

Raman microspectroscopy is already used to evaluate the effects of mechanical loading on polymers and thin films, as well as to study protein conformations. The Michigan researchers have set out to extend the Raman evaluation technique to the organic component of bone tissue, which they describe as "a highly ordered matrix composed mainly of collagen fibrils."1

The most recent experiments were performed on two specimens of femur bone: an unfixed cortical bovine specimen about 8 x 3 x 0.3 cm in size and an unfixed rat specimen about 8 cm long and 1 cm in diameter. The specimens were placed in a mechanical loading apparatus with clamps at either end. And a stepper motor was attached to one of the clamps to apply either tensile or compression stress to the specimen.

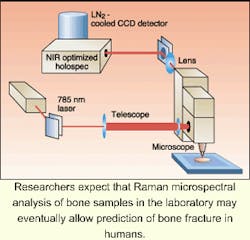

Raman spectral analysis was performed using an apparatus consisting of a 785-nm laser source coupled into the specimen through a modified epi-fluorescence microscope. And axial-transmissive spectrograph was used to disperse the Raman scatter onto a near-infrared-optimized, liquid nitrogen cooled, charge-coupled device (CCD) detector (see figure). Large shifts in the center of gravity of Raman spectral bands were observed for specimens under total global strain of about 7%, indicating a stress-induced change in protein conformation.

The focus of the experiment was on examining tissue around microcracks (generated by cyclic stressing of the bone specimens) in the bone in hopes of finding differences in the mineral composition of damaged bone as compared to normal bone. In previous experiments, Kohn, a biomedical engineering professor, and Michael Morris, a chemistry professor, scanned a laser line across a section of bone to create individual Raman line spectra that could be pieced together to create a Raman image of the bone and that provided an imaging method to examine previously identified microcracks in bone tissue under stress.2

The researchers observed that Raman spectral lines in bone with visible microcracks or diffuse damage were displaced significantly from levels obtained in bones with no visible microdamage, indicating a difference in chemical composition. He notes that spectra also exhibited broader peaks in the damaged bone indicating loss of structural stability.

"Our research on bone microstructure and microdamage mechanisms is obviously clinically related," Kohn said. "But reasons for starting out in a more basic science mode, rather than immediately working toward a clinical diagnostic, are the complexity of the analysis and the need to first develop structure-function relationships that will help us understand patient-based data."

REFERENCES

- M. D. Morris, A. Carden, R. M. Rajachar, D. H. Kohn, SPIE Proc. 4254, in press.

- J. A. Timlin, A. Carden, M. D. Morris, R. M. Rajachar, D. H. Kohn, Analytical Chem. 72(10), 2229 (May 15, 2000).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.