Scientists at ROLIC Research (Allschwil, Switzerland), are applying optical methods for patterning and aligning liquid-crystal displays (LCDs) to the development of antireflection coatings at potentially lower cost and broader utility than coatings based on traditional photochemical, deposition or mechanical techniques.

In April, the ROLIC team reported on antireflection coatings consisting of corrugated films based on blends of fully miscible and stable monomers, such as liquid-crystal prepolymers and monomeric liquid crystals.1 A key feature of their monomer corrugation (MC) method, in which prepolymers provide optical crosslinking, is the economical application of directional or anisotropic antireflection characteristics to surfaces with nonstandard shapes and sizes.

In addition to providing broadband antireflection and antiglare coatings, the researchers envision additional applications such as "aligning layers for LCDs, diffuse and directional reflectors, optically strong anisotropic retarders consisting of low birefringent materials, optical security elements, reflective and transmissive polarizers, diffractive optical thin films as well as polarization converters."

Isotropic coatings were fabricated by first coating the substrate with an MC film and then exposing it to ultraviolet light to crosslink the prepolymer components and induce phase separation. Liquid-crystal components were then removed, leaving a solid polymer film with an antireflective refractive index provided by a dense, isotropic distribution of pores with diameters smaller than the wavelength of light.

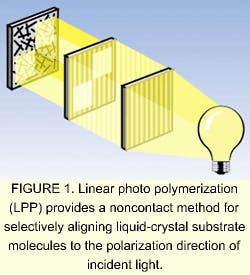

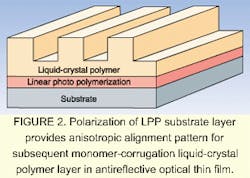

Anisotropic coatings were fabricated by either depositing the MC film on a substrate with an optically induced anisotropic surface topology or by using anisotropic MC phase separation techniques. Anisotropic substrate surface topologies were induced optically through ROLIC's linear photo-polymerization (LPP) process in which molecules in liquid-crystal substrates align their long axes with incident, linearly polarized ultraviolet radiation (see Fig. 1). Deposition of a liquid-crystal polymer MC film on such a substrate then yields a corresponding distribution of grooves and elongated pores in the antireflection coating (see Fig. 2).Factors such as film thickness, liquid-crystal prepolymer content, aligning direction of the substrate and energy of crosslinking radiation can be varied to tune the periodicity and height of grooves in the anisotropic MC films to produce optical gratings and thin-film elements for the types of applications mentioned above, according to the researchers. Capabilities for hybrid alignment were also realized through the interaction of elastic liquid-crystal aligning forces in the anisotropic surface structures with van der Waals forces of photo alignment.

The latter capability was tested by placing an additional LPP aligning film on top of the anisotropic MC film structure shown in Figure 2, which already has an LPP layer beneath it. By varying the ultraviolet exposure times in this upper layer, the researchers were able to shift the aligning direction of the layers and hence the function of the composite film from an opaque half-wave retarder to a transparent film. "A possible application would be in hybrid aligned optically stable LCDs," they wrote. "Such displays memorize their last switching state after disconnecting their power supply."

The ability to design anisotropic nano-topolgies is expected to allow fabrication of strongly birefringent films from weakly birefringent materials and from LCD materials with a relatively high optical stability that might prove useful, for example, in bright-light environments. In addition, increasing pore sizes into the micron range enables scattering in the resultant thin-film devices, which can then act as directional light diffusers and reflectors to increase the brightness and functionality of displays.

REFERENCE

- M. Ibn-Elhaj, M. Schadt, Nature, 410, 796 (April 12, 2001).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.