Researchers at the University of West Virginia (UWV; Morgantown, WV) have begun to collaborate with researchers at the Jet Propulsion Laboratory (JPL; Pasadena, CA) to develop an integrated optical monitoring (IOM) system for microelectromechanical systems (MEMS). A proof-of-concept IOM system developed at UWV with funding from the National Science Foundation is nearing completion, according to Lawrence Hornak, who described the UWV work in an invited paper last October in San Francisco, CA, during a symposium on micromachining and microfabrication sponsored by the International Society for Optical Engineering (SPIE). Hornak's team has also launched a three-year project with the JPL to adapt the technology into monitoring and control applications for NASA.

"We're looking at the merits of providing an optical signal for integrated optical monitoring of MEMS for immediate tasks such as positional control and velocity control, and also for long-term tasks such as enhancing device reliability," Hornak said. "Our first effort involved bulk optical monitoring of lateral comb resonators to provide real-time position control and vibration damping."

The team started with a lateral comb resonator in order to work with what Hornak described as a generic MEMS actuator. Electronic monitoring of such devices, as in capacitive measurements of device resonance, generally must be performed in a test mode, whereas Hornak is interested in using optics for continuous real-time monitoring of devices in operation.

In the initial project funded by the NSF, which the UWV team expects to wrap up next year, the IOM microprobe consists of a 1.3-µm wavelength beam of 15 to 20 µm in diameter that is directed through the MEMS device using diffractive optical elements. The 15- to 20-µm-diameter beam interacts with the edge of the MEMS structure and provides a diffraction pattern, while the 1.3-µm wavelength enables the beam to pass through the MEMS dye. The advantage of this approach is that it can be used without altering the structure of the MEMS devices to be monitored.

"There may be some constraints, in the mask, in the surface or in other areas, that can't be altered in a particular MEMS device," Hornak said. "Also, if you want a technology to be accepted, such as an integrated optical monitoring technology within a MEMS package, it's probably good not to ask people to change the design of their MEMS. Instead you'd like to have a transparent monitoring solution."

The collaboration with JPL, however, will involve incorporating a grating into the MEMS structure. "In other words, if it's a gear or a stage, openings in the poly layer generate a reproducible diffraction pattern when it is illuminated with the probe beam," he said.

NASA is interested in systems for lifetime monitoring of devices, in space, for instance, that would enable remote fault detection, diagnoses, and perhaps even device replacement. "One of the advantages of MEMS is that you can have an array of identical devices in a package so that when one starts to deteriorate you can switch to the next," Hornak said. "The other advantage is that you don't have to turn one device off and start the other one up."

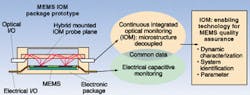

The goal is to provide a monitoring system that can anticipate device faults based on system parameters and seamlessly bring replacement devices online as appropriate. The NASA project will compare the usefulness of information obtained through IOM with information obtained through periodic electronic testing, but Hornak expects the final system to include both optical and electrical monitoring technologies (see figure).

"What we are really doing is exploring the applicability of a lot of techniques that are done in the macro world, but on a micro scale," he said. "The common denominator in all of this is to be able to monitor the state of the device decoupled from any of the drive mechanisms. In the macro world, that's where optical encoders and other things come in. Here we are using an integrated technique and heading toward monitoring of MEMS devices in a similar fashion."

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.