Gas-filled hollow-core photonic-crystal fiber laser emits at 4.6 µm

Gas-filled hollow-core optical fiber is a key development for pushing the wavelength of fiber lasers farther into the infrared (IR), particularly into the 3–5 µm atmospheric transmission window useful for remote sensing and free-space communications. One important type of mid-IR fiber for this purpose is the hollow-core photonic-crystal fiber (HCPCF), which can be fabricated from silica (SiO2) even though silica absorbs strongly as the mid-IR wavelength gets longer. Important for silica HCPCFs (and other types of hollow-core fibers as well) are advances in design that lead to a guided mode field that only weakly overlaps the glass cladding, minimizing absorption—which can lead to longer emission wavelengths. Now, researchers from the University of New Mexico (Albuquerque, NM), Xlim Research Institute (Université de Limoges, France), and the University of Modena and Reggio Emilia (Modena, Italy) have created a hollow core gas fiber laser emitting at 4.6 µm, which they believe is the longest wavelength generated inside a silica-based HCPCF. The emitter uses nitrogen oxide (N2O) as a gain material, pumped with an optical parametric oscillator (OPO) emitting 8 ns, 40 µJ pulses at 1.517 µm.

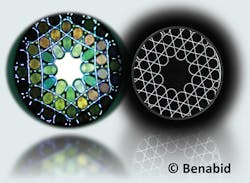

The fiber, which has an outer diameter of 300 µm and a core diameter of 85 µm, has a Kagome lattice cladding and a negative-curvature core contour that helps to inhibit the coupling between the light and the glass. The thickness of the struts in the Kagome lattice is about 490 nm. The gain of the experimental setup is high enough to produce lasing without the need for an external cavity. The researchers tried various gas pressures and found the maximum slope efficiency of 3% at a pressure of about 80 Torr. Because no attempt was made to maximize the laser output by fiddling with the laser geometry, a higher slope efficiency can be expected in the future. The researchers believe that their technique will allow extension of silica-based HCPCF laser wavelengths beyond 5 µm. Reference: F. B. A. Aghbolagh et al., Opt. Lett. (2019); https://doi.org/10.1364/ol.44.000383; image credit: Fetah Benabid.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.