Newsbreaks

PCFs and standard single-mode fibers are spliced with low loss

A roadblock to the use of photonic-crystal fibers (PCFs) in many applications is their inability to be easily coupled to standard single-mode fibers (SMFs) without suffering mode mismatch or, in the case of multicore PCFs, crosstalk problems. Even if the SMF and PCF modes are well matched, fusion splicing can cause deformation of the “holey” structure of the PCF, producing high splice loss. But, using fiber-drawing techniques, researchers in the Department of Physics at the University of Bath (Bath, England) have devised a method to efficiently join standard SMF to PCF (and even multiple SMF fibers to multicore PCFs).

The researchers construct a PCF preform in the usual way, but leave the central site empty (without a silica rod or tube). An intermediate preform (or ferrule) is drawn from the stack so that its central void is just large enough to fit a standard SMF fiber inside (slightly more than 125 µm across). The SMF is threaded into the void and one end of the ferrule drawn into a length of PCF of the desired dimension. The result is a standard SMF coupled to the PCF/SMF ferrule region, and a length of PCF-with typical losses of 0.6 dB at 1550 nm. Similarly, several SMF fibers can be threaded into a multicore PCF preform at desired locations, allowing each PCF core to be individually addressed without crosstalk with the others. Contact Tim Birks at [email protected].

Centrifugal oxygen generator improves COIL efficiency

Scalable to outputs of hundreds of kilowatts, the chemical oxygen-iodine laser (COIL) has a 1.3-µm wavelength that is well suited for conventional optical materials. The COIL is at the heart of the Airborne Laser being developed for the U.S. Air Force to shoot down missiles. At the Lebedev Physical Institute Samara Branch (Samara, Russia), researchers are improving the efficiency of the bubble-type singlet oxygen generator (BSOG) needed to produce the required singlet oxygen (the lowest excited state of the dioxygen molecule).

The trick to higher efficiency is to centrifuge the bubble layer (consisting of gaseous chlorine in hydrogen peroxide) in the BSOG, which reduces droplets in the oxygen flow. The researchers fabricated a supersonic centrifuge-powered COIL that reached a chemical efficiency of 25.6% and an optical output of 770 W. The laser cavity was 116 cm in length; the BSOG subjected the bubble layer to a 136-g acceleration. The ratio of output power to hydrogen peroxide consumption was higher than for COILs using the standard type of singlet oxygen generator. Contact Marsel Zagidullin at [email protected].

Diamond-turning technique creates complex surfaces

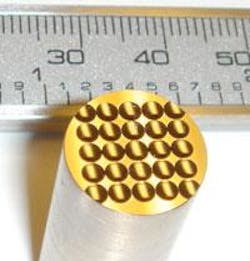

Researchers at Ohio State University (Columbus, OH) have developed a diamond-turning process that can directly fabricate complex optical shapes such as microlens arrays in a single machining step. Called a slow tool servo (STS), the process uses only ultraprecise feedback-controlled mechanical slides to position the cutting tool. Three orthogonal laser-controlled slides with a straightness of better than 250 nm resolve 8.6 nm at 1800 mm/min; the spindle turns at 6000 rpm.

Except for tip-radius compensation, the tool path is identical to the desired surface shape, following a single spiral and dipping and raising to create arbitrary surface shapes, including free-form and steep surfaces. Spherical microlens arrays with 5 × 5 elements were fabricated from copper-nickel and aluminum alloy; the array configuration was chosen because it was easy to characterize. Deviation from ideal shape was less than 1 µm (measured with a profilometer), while average surface roughness was 34.5 nm (measured with a phase-shift microscope). The researchers plan to use the STS-fabricated microlens arrays as molds for injection- or compression-molding of microlens arrays made of plastic or glass. Contact Allen Yi at [email protected].

Waveguide optical-power monitor is suitable for silicon photonics

Adding to the burgeoning list of devices suitable for silicon-based photonics, scientists at McMaster University (Hamilton, Ont., Canada) have developed an optical-power monitor integrated into a silicon-on-insulator waveguide. The monitor is sensitive at 1550 nm and extracts 19% of the optical power from the waveguide for measurement.

The single-mode waveguide is 3 µm wide and approximately 1 µm high. The waveguide is straddled by outlying n- and p-doped regions that, together with the waveguide, form a p-i-n photodiode; its IR absorption is enhanced by recombination at defect centers. Optical-quality waveguide end facets are created by a dicing saw and light is coupled into and out of the waveguide with tapered fibers. The photocurrent varies linearly with the device length and inversely with the separation between the p and n regions. Proton implantation greatly improves the sensitivity of the device. The average photon-to-electron conversion efficiency of a 6-mm-long device is 2%; a conservative estimate of its responsivity is 3 mA/W. The 19% loss in power translates to a 1.5-dB/cm attenuation. Fabrication of the device is fully CMOS-process compatible. Contact Andrew Knights at [email protected].

Transmultiplexing combines, converts 1310 to 1550 nm

In a technique called transmultiplexing, researchers at the Eindhoven University of Technology (Eindhoven, The Netherlands) have used nonlinear polarization rotation in a single semiconductor optical amplifier (SOA) to achieve error-free conversion of two 1310-nm 5-Gbit/s wavelength-division-multiplexed (WDM) signals into one 1550-nm 10-Gbit/s optical-time-domain-multiplexed (OTDM) signal. This all-optical capability avoids the bottleneck of optical-electrical-optical conversion of upstream 1310-nm communications from a fiber-to-the-premises (FTTP) subscriber into a 1550-nm network transmission window.

A 1310.9-nm and a 1313.8-nm source are intensity-modulated and multiplexed into one 1310-nm signal at 10 Gbit/s that is fed into the transmultiplexing SOA. This signal causes additional birefringence via carrier-density changes that causes the transverse magnetic and transverse electric modes to experience different refractive indices and thus a changed state of polarization for a second unmodulated 1550-nm signal that is input to the SOA. This results in the imprinting of the 1310-nm WDM signal onto the 1550-nm OTDM signal. The output polarization filter is adjusted such that the 1550-nm signal with rotated polarization passes through the polarization beamsplitter for analysis. Contact Jarek Turkiewicz at [email protected].

X-ray microscope resolves 15-nm features

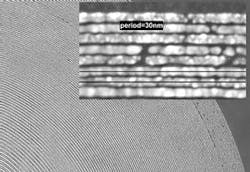

For elemental and chemical identification, techniques are needed that have spatial resolution on the nanometer scale. Using their XM-1 soft-x-ray microscope and a new fabrication method for its zone-plate lens, researchers at the University of California at Berkeley and its Lawrence Berkeley National Laboratory (both of Berkeley, CA) have reported sub-15-nm spatial resolution in a 250-eV to 1.8-keV spectral range (5- to 0.7‑nm wavelengths).

In zone-plate-based microscopes used at high magnification, the resolution depends on the outermost (or smallest) zone width of the zone plate; for example, a 25-nm outermost zone-plate width produces a 20‑nm spatial resolution. But using an overlay nanofabrication technique, outer zone widths of 15 nm (a period of 30 nm) have been achieved, resulting in sub-15-nm spatial resolution. Instead of fabricating one high-resolution zone plate, the researchers have fabricated two less-dense, complementary patterns and overlaid them with high accuracy. The zone plates were fabricated with Berkeley’s “Nanowriter” tool, which has a 6.5-nm-diameter, 100-keV electron beam and uses careful alignment algorithms to achieve a subpixel zone-placement accuracy of 1.7 nm. Contact Weilun Chao at [email protected].

Very-small-aperture laser diodes are characterized

Very-small-aperture lasers (VSALs) are targeted at reducing the optical spot size of a laser for the purpose of increasing data density in optical data storage. By applying subwavelength metallic apertures to the front facet of standard laser diodes, researchers at the Institute of Semiconductors at the Chinese Academy of Sciences (Beijing, China) have been able to evaluate the performance of these VSALs in terms of threshold-current density and lifetime.

After fabricating standard 650-nm laser diodes using commercial processes, the researchers deposited a metallic gold coating on the front facet into which a 250 × 500-nm aperture was formed. Because of the reflection back into the laser cavity from the gold coating (optical feedback) and the corresponding temperature and power density increase inside the laser-diode cavity, the VSALs have a lower threshold current, a smaller slope efficiency for the output power/drive-current curve, an enhanced redshift (longer-wavelength operation), and a shorter lifetime (output power decreases at a rate of about 0.002 mW/min) compared to standard laser diodes. Research in VSALs continues with the goal of fabricating devices that can withstand the high densities of light and temperature inside the diode. Contact Qiaoqiang Gan at [email protected].

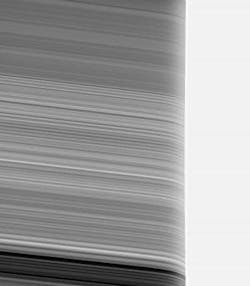

Saturn’s rings entertain again

As viewed by the Cassini orbiter, Saturn’s rings appear stunningly complex and strange (see Laser Focus World, August 2004, p. 28). Close up, the spacecraft continues to send back detailed images of the rings that to the uninitiated can be unrecognizable without an explanation.

In this view, taken in April of this year, the rings appear as a striped fabric that rolls back upon itself. In reality, they are passing behind the illuminated limb of Saturn, whose atmosphere refracts the light reflected from the rings, causing the ring structure to seem to bend. The image was taken with Cassini’s narrow-angle camera through a bandpass filter with a peak centered at 938 nm; the spacecraft was at a distance of approximately 197,000 km from Saturn. The image scale is 820 m per pixel. The filter transmits wavelengths that methane gas does not absorb, making the far-off rings visible through the upper atmosphere. By comparing this image to similar ones taken using filters with peak wavelengths absorbed by methane, scientists can estimate the vertical profile of haze and the abundance of methane in Saturn’s high atmosphere. See saturn.jpl.nasa.gov.

Superconducting detector counts photons within a pulse

Single-photon detection allows the construction of simple linear-optics quantum-computing gates that can handle up to two qubits (quantum bits). But a detector that counts (rather than merely detecting the presence of) photons in a pulse would enable computing beyond two qubits. A high-efficiency photon-number-resolving detector could also help characterize the optical outputs of parametric downconversion crystals, which are potentially useful for multiphoton lithography beyond the diffraction limit.

Researchers at the National Institute of Standards and Technology (Boulder, CO) have developed such a detector, which operates in the near-IR and visible spectral regions. The superconducting transition-edge sensor (TES) is a calorimeter that relies on the rapid change in electrical resistance near the superconducting critical temperature. The change in temperature is proportional to the sum of the individual photon energies in the pulse. The fiber-coupled device is cooled to 110 mK and contains a stack of TESs to improve efficiency, which reaches 88% at 1550 nm. Detectors operating in the UV and at efficiencies above 99% should be possible, say the researchers. Contact Sae Woo Nam at [email protected].