Plastic solar offers the promise of an expanding renewable-energy market

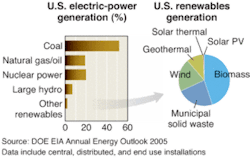

According to Strategies Unlimited (Mountain View, CA), photovoltaics (PVs) are a $7 billion global market growing at greater than 40 percent annually. This sounds tremendous until it’s compared with the overall energy market (see Fig. 1). Seventy percent of U.S. power is generated using fossil fuels, and renewable energy represents only 2%. Despite the enormous resource potential and the benefits of zero emissions and no fuel cost, photovoltaics remain a tiny fraction of renewable power. Of greater concern, Department of Energy, Energy Information Administration (DOE EIA) projections show very little change by 2025 when doing business as usual. Few will invest in technologies that depend on financial incentives or legislative support for survival. As the United States seeks to improve its energy security in a world facing increasing pressure on energy reserves, what will it take to significantly expand the reach of solar technology?

The answer lies in new materials and leveraging higher-volume manufacturing techniques. New nanostructured materials can make electricity readily available and unobtrusive in existing energy applications. Advances in nanotechnology and materials science have led to the development of materials made from conducting polymers and nanostructured particles. These plastic cells are then coated onto a surface in a continuous roll-to-roll process similar to photographic film manufacturing-no batch processing, no vacuum deposition, no clean room. The end result is light-activated plastic that is flexible, lightweight, lower in cost and more versatile in application than traditional silicon-based solar panels.

Conventional PV technology is evaluated on lifetime, efficiency, and cost, which limit the technology’s commercial viability because of the inherent limitations of existing products. Photovoltaics are most commonly measured on cost per kilowatt-hour produced because it competes with electricity supplied by the grid or diesel generators. Because of the high initial cost associated with materials used for traditional photovoltaics, long life is critical to ensure sufficient hours of output to pay back the initial investment.

Crystalline silicon technology represents more than 90% of the existing solar market and is a mature technology. The initial capital investment for a crystalline silicon plant is about $1 million per megawatt, and plant construction takes 18 months, with an additional 12 months to achieve full capacity. Only incremental reductions in material costs can be realized, so the economics cannot change substantially enough to create a shift in applications and market reach. High area-related costs (structure, site preparation, wiring, and installation) associated with mounting traditional PV on buildings or the ground place further pressure on the technology’s life and efficiency.

Plastic solar offers advantages

Inexpensive large-scale manufacturing of plastic solar cells capitalizes on roll-to-roll coating techniques. Some thin-film solar cell manufacturers describe their processes as roll-to-roll, but this refers to the application of laminate only. The actual manufacture of thin films utilizes vapor-deposition platforms operating under vacuum, which accounts for large capital investments (more than $2 million per megawatt).

Materials and manufacturing costs for plastic solar are low, including the capital cost for new capacity. Proven coating and printing know-how from the chemical and flexible electronics industries enable polymer PVs to be manufactured in a continuous roll-to-roll process that is significantly less expensive and capital-intensive than the multistep assembly of traditional solar cells. The process is simple, energy efficient, environmentally friendly, replicable to multiple plants, and scalable to high volumes. The lower manufacturing costs mean lower product costs (about one-third that of traditional solar).

Another significant advantage is low-light performance. Konarka’s plastic solar cells’ photovoltaic nanotechnology converts light to energy anywhere, performing better under indoor light and producing power outside during the dusky early morning and late afternoon hours.

The material’s paradigm-changing form factor allows power-generation capabilities to be integrated directly into any device, system, or structure that has a battery. Its lightweight, conformable plastic can be rolled, folded, cut into different sizes and shapes, and produced in colors to blend with whatever it is attached to.

The flexibility, conformability, performance, price, and weight of this light-activated material enable expansion into new product directions. Integration of plastic solar cells into the systems design for lighting, sensing, communicating and computing extend and enhance battery life without increasing or otherwise impeding the form factor of product designs. Photovoltaic fibers and durable plastics bring power-generating capabilities to structures, including tents, awnings, roofs, and windows. Consumer electronics, such as mobile phones and portable music players, and business products, such as networked electronics, laptops, and PDAs, can be operated longer without the need to plug them into an outlet. Military applications include battery charging on the battlefield, remote power for soldiers and unmanned vehicles, and solar-powered sensor networks.

Innovations in nanotechnology have created the possibility to truly transform solar power into a powerhouse renewable energy source. With plastic solar cells, solar no longer needs to be a separate aftermarket system constrained by weight, size, rigidity, or installation concerns. Any electronic can be empowered to convert available light to power using a fully integrated renewable-energy generator making solar practical, affordable, and universally available.❏

Daniel Patrick McGahn is the executive vice president and chief marketing officer at Konarka Technologies, Inc., 100 Foot of John Street, Boott Mill South, 3rd Floor, Suite 12, Lowell, MA 01852. [email protected]