Hollow-core fibers make efficient gas cells

Gas cells are used as frequency references for a variety of laser-based applications; however, these cells are usually bulky, are difficult to integrate in a practical and compact setup, and cannot easily guide light over long lengths in a single transverse mode. But researchers in the photonics and photonic materials group in the Department of Physics at the University of Bath (Bath, England) are reversing this notion with the development of gas-filled hollow-core photonic-crystal fibers (PCFs).1 The researchers have already demonstrated two different PCF gas-cell devices: a hydrogen-filled cell for generation of rotational Raman scattering using quasi-continuous-wave laser pulses (see Laser Focus World, November 2004, p. 19); and acetylene-filled cells for frequency-locking of diode lasers.

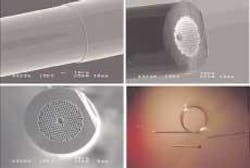

The fiber gas cells consist of a hollow-core PCF filled with gas and spliced hermetically at both ends to standard single-mode optical fiber (SMF). The use of PCF, in which light is guided in a single transverse mode via a photonic bandgap created in the cladding, increases the efficiency of these devices. After some practice, the researchers were able to fusion-splice the fibers without significant deformation and collapse of the PCF microstructure (see figure). Although initial results produced an insertion loss of 1 to 2 dB, the researchers estimate that a perfect splicing procedure could yield a loss of 0.6 to 0.8 dB, with 0.4 to 0.6 dB estimated to be due to modal-field mismatch between the single-mode fiber and photonic-crystal fiber. The additional losses are most likely due to a deformation in the end face of the PCF when heated in the splicer.

Filling and sealing

To prevent contamination of the splice by solid deposits and water condensation (and to prevent combustion of flammable gases such as hydrogen and acetylene), the splicing region is continuously purged by argon gas. The mechanical strength of the splices is equivalent to a gas pressure of 80 bar-more than adequate for containment of gases at high pressure.

To form a gas cell, one end of the PCF is fusion-spliced to SMF. The PCF is then evacuated for several hours (depending on the length of the fiber) from the remaining open end to a pressure of approximately 1 µbar before being backfilled with the desired gas. Once the desired fill pressure is achieved, the second end of the PCF is fusion-spliced to SMF. The acetylene gas cells were made from PCF with a guidance band centered at 1550 nm with a loss of 18 dB/km, and the hydrogen cells had a guidance band centered at 1064 nm and a loss of 60 to 70 dB/km.

Using the hydrogen gas cell, the researchers were able to generate rotational stimulated Raman scattering (SRS) in the 5-m-long in-line cell using quasi-continuous-wave pulses. In SRS, photons from the incident pump laser-a Q‑switched Nd:YVO4 (vanadate) laser operating at 1047 nm with tunable pulse width from 6 to 50 ns-are converted to photons of lower frequency through interactions with molecules in an excited vibrational or rotational state. Due to the long interaction length enabled by the unique construction of the PCF hydrogen gas cell, powerful lasers were not necessary; SRS was generated with pump pulses as long as 35 ns with peak powers of only 100 to 180 W.

Next, the researchers fabricated a laser-diode reference in the 1550-nm telecommunications range using an acetylene gas cell. To illustrate the operation of the wavelength comb, they built an all-fiber frequency-stabilization system using a side-locking technique to lock to one of the shoulders of a selected absorption line. The setup consisted of a tunable extended-cavity laser-diode source, an isolator, two couplers, and a length of acetylene-filled hollow-core PCF. The closed-loop frequency fluctuations of the laser were measured to have a root-mean-square frequency deviation of about 310 kHz over a one-minute integration time. To the researchers’ knowledge, this is the first time a completely fiber-based frequency-stabilization and testing system has been shown.

“The fact that our design is based on hollow-core photonic-crystal fiber achieves three goals,” says Fetah Benabid, one of the researchers. “The first is compactness, the second is integrability with current technology components, and the third is the huge enhancement in efficiency. I do believe that this device will have huge implications in a lot of industrial applications, ranging from laser sources, telecommunications, and global positioning systems to more futuristic ones, such as quantum computing.”

REFERENCE

1. F. Benabid et al., Nature 434, 488 (March 24, 2005).