Newsbreaks

Algorithm is ‘search engine’ for virtual 3-D objects

The modeling of 3-D objects (with surfaces consisting of many small polygons) for computer-aided design, computer graphics, and other applications gives rise to stored libraries of 3-D objects that can be drawn upon for various purposes. But a large enough library of virtual 3-D objects leads to the problem of how to retrieve the object that best fits user-defined criteria. Researchers at Chung Hua University (Hsinchu, Taiwan) have developed a content-based retrieval algorithm that finds objects in a way that is resistant to error.

One existing approach, defining a 3-D object by its various 2-D silhouettes, falls prey to even small object rotations or deformations. Other methods include identification of principal axes of objects, calculating the histograms of object curvatures, and so forth, but these approaches also are prone to errors. In the new approach, the 3-D object is set at the center of a voxel grid (based on the object’s center of gravity) and normalized in size. Voxels containing polygons are identified; a distribution of the distances between the identified voxels identifies the object. In a retrieval experiment, the algorithm’s recall efficiency reached 0.257; though low, this is higher than efficiencies achieved by other algorithms. Contact Chang-Hsin Lee at [email protected].

Quasi-single-mode fiber laser nears 2-kW output with high-quality beam

A ytterbium single-fiber laser developed by engineers at IPG Photonics (Oxford, MA) is the most powerful (1960 W) and the most intense (1300 W of that power falling within the diameter of a diffraction-limited spot) yet developed. The quasi-single-mode laser has a beam quality M2 of 1.2 and emits at 1075 nm with a linewidth (full width at half-maximum) of less than 10 nm.

The laser has three pumped stages. An oscillator contains 10 m of active fiber with a 10.6-µm core, while a first amplification stage is contained within a 6-m length of 12-µm-diameter-core fiber. A second amplification stage has 9 m of fiber with a slightly larger core. A passive-delivery fiber 2 m long with a 15-µm core is terminated with a collimator that produces a 7-mm-diameter beam. The pumping scheme was crucial to the achievement. Each of many laser-diode pump units in the final amplification stage delivers 20 W of in-fiber power into a numerical aperture of 0.14. The fiber laser has an electrical-to-optical (wall-plug) efficiency of greater than 20%. Contact Denis Gapontsev at [email protected].

Monolithic quantum-well IR detector is sensitive up to 75 GHz

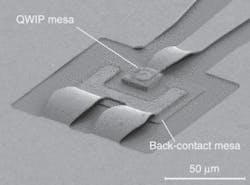

A group at the National Research Council of Canada (Ottawa, Ont., Canada) developing ultra-high-frequency quantum-well IR photodetectors (QWIPs) has demonstrated its latest achievement-a monolithically integrated QWIP that operates at frequencies up to 75 GHz. Fabricated on a gallium arsenide substrate, the detector is assembled in a compact package.

The device has a 100-layer structure and is most sensitive to the 10.3- to 10.6-µm spectral region. The detector is mounted to a brass block that also contains a microwave connector for the output signal. In the device itself, both the QWIP and the back-contact mesas are connected to conductors on the substrate via air bridges. The detector was characterized in a test at 100 K; the modulated light source was a heterodyne combination of two carbon dioxide lasers that could cover various regions from 34 to 74 GHz. The QWIP had a dark current of 18 µA, an optical efficiency of 98.2%, and an optical repeatability of 6%. A drop in the heterodyne resistance above 40 Hz resulted from the connector and coaxial cable used. A second device with a different connector had a response at 70 to 75 GHz that was 35% of the zero-beat response. Contact Peter Grant at [email protected].

Cesium gas laser is pumped with diode source

Although gas lasers can have improved beam quality with fewer thermal effects compared to flashlamp-pumped or even diode-pumped solid-state lasers, electrical discharge or optical pumping with a dye laser or discharge lamp results in these gas lasers having low efficiency. But recently researchers at the United States Air Force Academy (USAF Academy, CO) demonstrated a cesium (Cs) vapor laser that is pumped with a 400-mW laser diode and achieves a slope efficiency of 41% with a threshold power of 67 mW and an output power of 130 mW.

Using a three-level pump scheme where Cs atoms are pumped to a transition level by an 852-nm diode laser with the help of an ethane buffer gas, a population inversion is created that produces lasing at 894 nm. The 2.5-cm-long Cs vapor cell was placed inside a 16.5-cm laser cavity and longitudinally pumped through the input cavity mirror. The researchers expect to increase the slope efficiency to 60% by improved matching of the pump beam and the laser-cavity mode profiles. Contact Thomas Ehrenreich at [email protected].

Organic-polymer optical sensor detects TNT

Semiconducting organic polymers (SOPs) are used as chemical sensors due to the fact that electron-deficient “nitroaromatics” or explosive analytes such as 2,4,6-trinitrotoluene (TNT) can bind to the electron-rich SOP and quench (or inhibit) the lasing of the polymer through electron transfer. This lasing reduction can be measured and the presence of a chemical can be determined.

To improve this sensitivity, researchers from the Massachusetts Institute of Technology (Cambridge, MA) developed a new polymer with a high optical-damage threshold and low lasing threshold that is 30 times more sensitive to the explosive vapors of TNT than previous materials as a result of its structure. The researchers showed that when their SOP was pumped at intensities near the lasing threshold, only a very small (parts-per-million) presence of the analyte was necessary to reduce lasing. With further refinements to the polymer, the team expects to see lasing cessation when parts-per-billion quantities of the targeted chemical are present. The researchers have demonstrated this improved sensitivity when the polymer is fabricated into simple waveguides, applied over distributed-feedback gratings, or used as a coating on optical fiber. Contact Timothy M. Swager at [email protected].

Diamond on fiber endface guides fluorescence

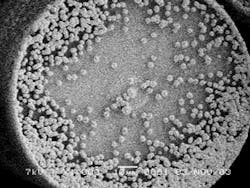

Scientists at the University of Melbourne (Victoria, Australia) have developed a chemical-vapor-deposition (CVD) technique for depositing diamond crystals on the endfaces of optical fibers. The technique allows fluorescence emission from the optically active diamond to be directly coupled into the fiber, a necessary step in the development of a fiber-coupled single-photon source.

Diamond with optically active centers was grown by adjusting the nitrogen-doping levels in a standard CVD process. Fiber substrates were prepared by cleaving and bundling 50 to 100 individual 1.5-cm-long fibers. The fiber surfaces were seeded by exposing the fibers to ultrasonication (application of ultrasonic frequencies in a liquid) in a diamond/metal powder slurry. The fibers were loaded into the reactor chamber with the seeded end of the cleaved fiber bundles facing up toward the plasma. Conditions for diamond growth were typically 1.2‑kW microwave power at 30-Torr pressure and 700°C temperatures for a 4-hour growth run. A 10-mW, 514-nm laser beam was focused onto the diamond at the core of the optical fiber and a spectrometer confirmed the characteristic Raman peaks at 552 and 558 nm expected from CVD-grown diamond. Contact James Rabeau at [email protected].

DCCFs form temperature-insensitive flattening filter

Fiberoptic spectrum-flattening filters are useful in optical-coherence tomography as well as in wavelength-division multiplexing. Conventional flattening filters based on fiber gratings, however, are sensitive to temperature fluctuations, requiring environmental control. Researchers at the Institut de Recherche en Communications Optiques et Microondes (Limoges, France) have developed a flattening filter based on dual-concentric-core fibers (DCCFs) that eliminates the problem of temperature sensitivity.

A DCCF has a small high-refractive-index central core surrounded by a low-index ring, a larger moderately high-index ring, and a low-index cladding. The single mode of the central core can couple with modes in the higher-index ring, with the coupling dependent on wavelength-resulting in a fiberoptic spectral filter. To flatten the output of a diode-pumped broadband amplified-spontaneous-emission fiber source, the researchers use three sections of DCCF, each with an approximately Gaussian transfer function at a different wavelength; the length-optimized sections are spliced together and to end sections of standard single-mode fiber. For a spectral region from 1532.6 to 1561.4 nm, the power variation in the spectrum was reduced from 5.8 to 1.4 dB. Temperature sensitivity was less than half that of a fiber-grating filter. Contact Sébastien Février at [email protected].

Ultrafast pulses write waveguides in silicon

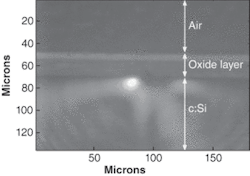

Silicon (Si) lasers and optical modulators have been demonstrated and promise all-Si optical integrated circuits. Another essential ingredient has been developed at the University of Toronto (Toronto, Ont., Canada) and the Friedrich-Schiller-Universität Jena (Jena, Germany), where researchers have for the first time used ultrafast-laser pulses to write waveguides in crystalline Si.

Pulses from a Ti:sapphire laser were passed through an optical parametric amplifier to generate 150-fs pulses with a 2.4-µm wavelength, chosen to drive nonlinear three-photon absorption in oxide-coated Si. A reflective objective focused the beam. The Si became amorphous and mechanically stressed, resulting in an anisotropic increase in refractive index. Focusing to a depth of 90 to 130 µm in the Si produced the best-quality waveguides, which appeared at only 5 to 20 µm below the surface. The single-mode waveguides guided light at 1550 and 1320 nm and confined only the polarization perpendicular to the surface of the Si. A loss of 1.2 B/cm was observed at both wavelengths. The induced refractive-index change was estimated to be about 0.001. Waveguides have also been written in non-oxide-coated (bare) Si. The laser-writing process can be combined with CMOS fabrication technology, say the researchers. Contact Amirhossein Nejadmalayeri at [email protected].

Quantum-cascade laser operates up to 400 K

The first demonstration of above-room-temperature operation of gallium indium arsenide/aluminum arsenic antimonide (GaInAs/AlAsSb) quantum-cascade lasers has been reported by scientists at the Fraunhofer Institute for Applied Solid State Physics (Freiburg, Germany). The lasers emit at 4.5 µm and can be operated in pulsed mode up to at least 400 K (127°C).

To fabricate short-wavelength quantum-cascade lasers, a large quantum-well depth is required. The use of GaInAs/AlAsSb heterostructures for quantum-cascade lasers is attractive because they offer a large direct conduction-band offset (quantum-well depth) of 1.6 eV, and they can be grown lattice-matched on indium phosphide (InP) substrates offering good material quality and the possibility of being combined with InP waveguides for optical confinement. The Fraunhofer scientists used 25 periods of alternating active/injection regions as the light-emitting source, sandwiched between two silicon-doped GaInAs separate-confinement layers, grown on a sulfur-doped InP substrate using molecular-beam epitaxy. The growth procedure was followed by additional growth layers of InP to serve as upper waveguide claddings and contact layers. After being processed into ridge-waveguide laser bars, the 2.8-mm-long, 18-µm-wide laser exhibited a 750-mW peak power per facet at 300 K and a 30-mW power per facet at 400 K. Contact Quankui Wang at [email protected].