Recent achievements in silicon nanophotonics have reinvigorated the search for the monolithically integrated optoelectronic integrated circuit, or OEIC. One application that is getting a lot of attention is the chip-to-chip or on-chip interconnect. The clock speed in microprocessors is scaling so fast that soon, chip- and board-level copper interconnects may limit the performance of computers. Fiber optics engineers are therefore anxious to introduce optical interconnects at the chip level to improve the clock or interconnect bandwidth, reduce jitter and skew, and so on. Such a development would continue a steady march in technology dating from the 1980s, and finally achieve a commercial application for OEICs. But is this the right application for OEICs?

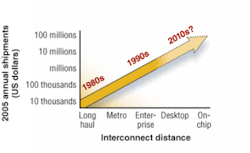

Optical interconnects began with long-haul telecom routes, today requiring tens of thousands of new transmitters each year. Interconnect technology has progressed to shorter backbones for enterprise storage and server systems, with annual shipments now in the millions of units per year. There are optical interconnects already in the backplanes of large computers, such as supercomputers and terabit routers, although today these interconnects are limited to only the highest performance systems. A vastly larger volume would be possible if optical interconnects were to reach inside the microprocessor itself. For example, volumes for multipurpose micro processors for personal computers today already exceed 200 million units annually (see figure).

Such a scenario has a basic flaw, however. It attempts to solve the challenges of electronics using high-performance optics, but at costs lower than any optical interconnects have achieved previously. It requires a fully developed optical solution that the computer industry can incorporate into products, which might be likened to jumping onto a speeding train. A start-up company might attempt such a leap, but such stunts run counter to the behavior of large companies and of engineers in mid-career with everything to lose if the leap falls short. Meanwhile, electrical interconnects continue to improve, and designers are perpetually considering new and more cost-effective architectures.

More important, it’s not clear that customers are basing buy decisions on sheer speed. There will always be demand for a processor that operates at record-breaking speed, of course, but what about the bulk of the market? A Mazerati can go fast, but the Toyota Prius is more affordable and energy efficient. Do more people buy the Mazerati or the Prius?

As described in Clayton Christiansen’s classic work, The Innovator’s Dilemma, legacy disk-drive makers pursued higher-capacity products to please their customers, while new companies created new markets with smaller, lower-capacity drives. The new lower-performing category repeatedly beat out the higher-performing category. Today, even large storage systems use 3.5-in. disk drives, which turned out to be more cost-effective and more reliable than larger drives.

A more attractive market for OEICs, then, may be in a lower-performance product like optocouplers. Optocouplers are not as sexy as microprocessors. They convert an electrical signal to light, and convert it back to an electrical signal in another circuit, merely isolating the electrical noise in the circuits. Optocouplers, which sell from less than a dollar to, at most, a few dollars, are nearly commodities, and there is tremendous pressure on manufacturing costs and margins. This might not seem at first to be a very attractive application for optical integration. It seems like wasting an expensive Mazerati engine on a motorcycle, or a golf cart!

STMicroelectronics (Geneva, Switzerland) appears to be thinking otherwise, however. ST successfully demonstrated light emission from silicon, which allows it to make an optocoupler from a single substrate material, instead of bonding silicon with III-V semiconductors. The performance of the silicon emitter doesn’t need to be very good because the emission travels over less than a millimeter. The innovation could give ST just enough of an advantage to enable significant reduction of optocoupler manufacturing costs.

Another opportunity may lie in sensors. The sensor market is really a wide range of mostly niche businesses. Many use optics. The optics in many of these sensors do not require sophisticated features or performance; they need only to be reliable and inexpensive. And, some products have potential for large-volume sales, such as those for use in homes, cars, homeland security, and public safety.

In such volume applications, characterized by need for low manufacturing cost, an integrated sensor using silicon photonics, much like the monolithic opto coupler, may be just the solution. The high-end “Mazerati” applications certainly bring the most media attention, but we should keep our minds open for other opportunities more like a “Prius,” or even a motorcycle. If history is a guide, the best opportunity may be right in front of us.

About the Author

Dr. Tom Hausken

Director, Photonics and Compound Semiconductor Products

Joining Strategies Unlimited in 1999, Dr. Hausken conducts the world’s leading market research in lasers and other photonics markets. He has nearly 30 years in the industry, including a joint project with Japan on optical computing while at OIDA, technology policy at the U.S. Congressional Office of Technology Assessment, and in R&D and production at Alcatel and Texas Instruments. He has a PhD from the University of California at Santa Barbara in compound semiconductor photonics.