FIBER AMPLIFIERS: Coiling boosts single-mode power in multimode fiber

Researchers from Sandia National Laboratories (Livermore, CA) and the Naval Research Laboratory (NRL; Washington, DC) presented a technique for exceeding the current V-number limit of 2.405 for constructing a single-mode optical amplifier. The researchers expect the technique to allow scaling of pulsed fiber lasers and amplifiers to much higher powers than are currently attainable due to pulse-energy limitations caused by low energy storage and nonlinear processes in fiber.

The potentially ameliorative technique consists of coiling a multimode fiber and adjusting the radius of curvature to introduce a bend loss that preferentially suppresses signal modes of order higher than the fundamental. "If you strategically choose the radius of curvature, you can discriminate between the higher-order modes and the fundamental mode," said Dahv Kliner, a senior research scientist at Sandia who collaborated with Jeffrey Koplow and Lew Goldberg at the NRL to develop the technique. "So you can introduce a significant amount of loss for LP11, which is the first mode above the fundamental mode, and get a substantial suppression of LP11 and all higher-order modes compared to the fundamental mode LP01."

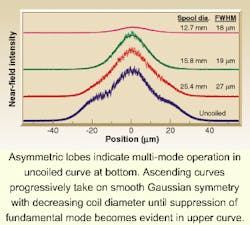

In their experiments, described during a technical presentation at the annual Conference on Lasers and Electro-Optics (CLEO; San Francisco, CA) in May, the researchers used a 6-m length of ytterbium-doped double-clad fiber with a core diameter of 25 µm and numerical aperture of 0.1, which yielded a V-number of 7.4 for a 1064-nm signal. A pump of 974 nm was used in the testing. Pump power was set at 3.9 W, and the near-field spatial profile of the copropagating amplified spontaneous emission (ASE) was measured by a linear diode array. ASE uniformly excites all modes of the fiber. A coil diameter of 1.58 cm enabled single-mode operation without excessive suppression of the fundamental mode (see figure).1

In comparing the slope efficiency of coiled and uncoiled versions of the amplifier seeded at 1064 nm, the researchers found a 2% difference, Kliner said. "In other words, we had not significantly compromised the performance of the amplifier. We had not induced significant bend loss to the lowest-order mode, so the slope efficiency was not changed." The amplifier threshold did change by about half a watt, he said, probably due to the filtering effect of removing the higher-order modes. They also measured a value for M2 of 1.09 ±0.09 for the ASE source, essentially indistinguishable from unity within the accuracy of the measurement.

A significant advantage of the bend-loss technique is that it can be used along with other methods of inducing single-mode operation in multimode fiber, such as manipulating the index profile, concentrating dopant near the longitudinal axis of the fiber core, or controlling the launch conditions of the seed beam, Kliner said. "You can apply this method to any fiber. You don't need a complex dopant distribution or index distribution, but it's fully complementary to other approaches."

Potential problems from nonlinear processes such as stimulated Brillouin scattering, stimulated Raman scattering, and self-phase modulation are also avoided due to the relatively large mode-field diameter and short fiber length of an amplifier fabricated in multimode fiber. The researchers have calculated that the bend-loss method may enable single-mode amplification in low-numerical-aperture multimode fibers with core diameters in excess of 50 µm.

Potential pulsed applications at high peak powers include nonlinear frequency conversion to the visible and ultraviolet; pumping an optical parametric oscillator (OPO), performing difference-frequency generation into the infrared, or transmitting ultrashort pulses along optical fiber, Kliner said. Continuous-wave applications include pumping an OPO to provide a narrow linewidth at high average power for chemical sensing.

REFERENCE

- J. P. Koplow, D. Kliner, and L. Goldberg, Opt. Lett. 25(7), 442 (April 1, 2000).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.