MICRODISPLAYS: Virtual reality products introduce psychophysics

RICK CONNER

Recent market reports suggest that by the year 2004 the annual volume of microdisplay products could be in the billions. This technology will certainly create many new challenges for the image-processing world, as well as for the social fabric. The facts that microdisplay technology can be virtual-reality oriented and that its widespread use seems imminent are likely to hasten the evolution of a communications environment in which language becomes a complicated interpretation of real and virtual experiences. From a manufacturing perspective, all of this raises interesting questions as to what factors will become most important in the quality control of microdisplay products and components.

Definition of a microdisplay

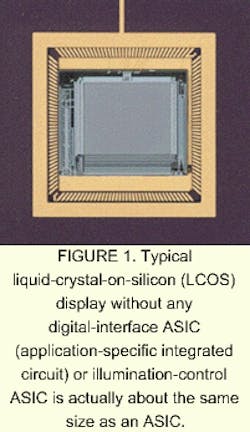

In the most fundamental terms, a microdisplay unit is a miniature device that creates images and projects them into real or virtual space. Many experts in the industry define a microdisplay unit as a flat-panel device measuring less than 1.5 in. on the diagonal and requiring magnification or projection for proper perception by the intended observers (see Fig. 1). A microdisplay is not to be confused with a miniature display. Miniature displays are flat-panel devices measuring from 1.5 up to about 5.0 in. on the diagonal and are primarily built for direct view (a 1.8-in. active-matrix liquid-crystal-display pocket television, for instance).

One example of a microdisplay that might project into virtual space would be a system that replaces a notebook display with a microdisplay imbedded within an eyewear piece. The system also would include appropriate optics to create a virtual image that appears to be the same size and distance away as a regular notebook display. Another example would be a head-mounted microdisplay device that provides real-time infrared (IR) video images to a surgeon of his or her hands performing the surgery. Again the system would also include the optics to project this view into the surgeon's virtual space. Ultimately, this head-mounted technology can evolve into an immersive virtual reality that simulates new worlds and objects. The surrounding sensory interfaces would include vision, audio, tactile, olfactory, and motion, embracing the observer in a full separate reality.

Microdisplay systems that project into real space include multimedia projectors, big-screen TVs, and computer monitors. The microdisplay units are enclosed in these systems and various optical configurations project the images onto a display screen. Broadly speaking, current microdisplay applications can be combined into either microdisplay projectors (high-definition TV, presentation technology, PCTV, high-definition monitors, and television) or microdisplay personal displays (cameras, network appliances, and PC monitors).

Psychophysics of inspection

In general terms, display (micro, miniature, large, virtual, holographic, and so on) inspection must include more than measuring the functionality and fidelity of the display device. It must also include how observers actually perceive images, specifically their direct visual experiences (such as the response of the eye to a given array of colors), their emotional experiences (did the image trigger the reaction that was intended by the creator of the image?), and their mental experiences (did the scene cause the observer to focus on certain parts of the image and to miss the overall meaning?).

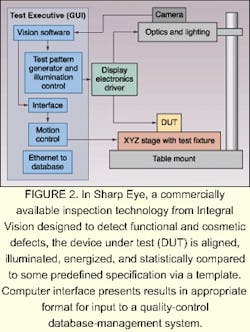

The process can get even more involved. For instance, was the observer able to use an 'image map' to find the actual location of an event at some point in the past? Ultimately, the inspection process will have to account for the psychology as well as the physics of a situation, thus the term psychophysics (see "Highlights of psychophysics," bottom of this page). Even a perfect machine-vision inspection system with artificial intelligence would not be able to objectively and comprehensively determine all of the relevant factors. Consequently, the creation of any sort of absolute display inspection standard to include psychological as well as physical effects is likely to become unwieldy. And currently, experts in the business of display measurement and calibration don't attempt it. The focus is primarily on the fidelity and legibility of the display relative to the visual response of the observer (see Fig. 2).

Performance parameters

Any display measurement must answer two fundamental questions—what measurements are to be made and what specification are these to compare with. These obvious questions are often difficult to answer. Let's say that a manufacturer's laboratory creates an ideal microdisplay lens with a minimal number of defects, such as aberrations, scratches, particles, and inclusions. The laboratory may propose this condition of minimal physical defects as a final specification for a product. Another group in the same company may just want to know what the consumer will 'put up with' without rejecting the product. Such a specification might be obtained through a normalized consumer study. The CEO of the company might come along and look at the product, based upon either of the above specifications, and say, "No one would buy a product with that many scratches on it!" Even a passing appreciation of the possibilities for confusion within one company leads to a profound appreciation of the importance of industry-wide standards.

The two international bodies that deal with display standards are the International Electro-technical Commission (IEC) and the International Organization for Standardization (ISO). Currently these organizations don't have formalized microdisplay standards because of the infancy of the market. But the imminent prospects for rapid market expansion indicate that standards will have to grow also.

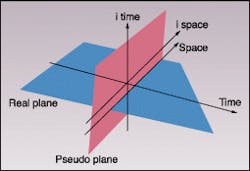

From the psychophysical perspective, the display device must be understood as a visual stimulus to the relative observer, such that both viewer and device are immersed in an illuminated environment. In this context, the observer's perceptions of images are a function of the space and time dependence of measurable parameters such as luminance/chromaticity, lighting, and viewing direction. Spatially dependent parameters typically include resolution, uniformity, crosstalk, distortion, and contrast. Time-dependent parameters typically include flicker, the response time, and the sticking effect.

By way of definition, spatial resolution is the size of the smallest feature reproducible by the display or the minimum distance between two image features so that these can be perceived as separate. Uniformity is the map of luminance and chromaticity variations. Crosstalk is the variation of luminance/chromaticity due to the coupling effects of addressing adjacent pixel areas. Distortion causes the geometry of certain features to deviate from the template geometry. The image must also be adequately contrasted from its surroundings, meaning that it can be seen in terms of its true luminance and color contrast.

Temporal parameters are equally important. Images need to appear stable to the observer, not to flicker, jitter, or smear. The luminance rise and fall time between two stable states must fit within some specification. And spurious memory effects that cause image ghosting must be eliminated.

The psychophysics of inspection also raises broader questions. How does cognition interpret virtual images in motion? What are the best space and time positions for virtual environments that give the observer multiple images 'simultaneously'?

How will machine vision interpret the realism or reliability of virtual images? In a network of observers, how will we map the captured and projected virtual images?

In sum, we are entering an era of virtual-image-driven technology, and microdisplay devices represent the first wave. The versatile and ubiquitous nature of this technology will challenge the presently limited world of device fabrication and inspection to expand its boundaries and embrace knowledge from psychology, physics, and other diverse disciplines.

Rick Conner is sales manager for Integral Vision, 37800 Grand River Ave., Farmington Hills, MI 48335; e-mail: [email protected]; www.iv-usa.com.