WAVEGUIDES: Ceramic ribbon allows gigahertz transmission

Until recently, low-loss solid-fiber waveguides have been no-shows in the 30- to 3000-GHz transmission band. The main limitation was not eliminating impurities in the material, but the presence of intrinsic vibration-absorption bands. Researchers at the Jet Propulsion Laboratory (JPL; Pasadena, CA) and colleagues at The Aerospace Corp. (El Segundo, CA) may have solved this problem through a combination of material and waveguide geometry—specifically, ceramic alumina and a ribbon-like structure with an aspect ratio of 10:1.

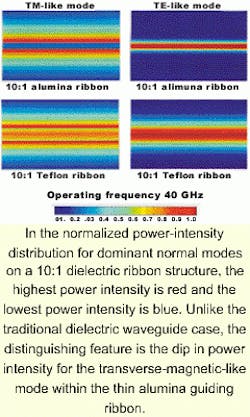

According to JPL scientist Cavour Yeh, the alumina waveguide has an attenuation factor lower than 10 dB km-1 in the 30- to 3000-GHz region, which is more than 100 times smaller than that of a typical ceramic circular-rod waveguide.1 For example, the attenuation constant for a Teflon dielectric waveguide is 1.3 dB m-1 at an operating frequency band near 100 GHz and 2.4 dB m-1 for a conventional metallic rectangular waveguide. The attenuation constant of the JPL microstripline device is estimated to be 3 dB m-1 (see image).

The researchers found that the ceramic-ribbon structure can support two dominant modes with no cutoff frequency. These include a transverse-electric-like dominant mode with most of its electric field aligned parallel to the major axis of the ribbon and a transverse-magnetic-like dominant mode with most of its electric field aligned parallel to the ribbon's minor axis.

"As the material loss factor and the dielectric constant of a solid are fixed," said Yeh, "the only way to reduce the attenuation constant is to find the proper cross-sectional geometry for a waveguide. After performing a systematic normal-mode study on a variety of geometries, we determined that a ribbon-shaped guide made with a low-loss high-dielectric-constant ceramic material such as alumina can yield an attenuation constant for the dominant transverse-magnetic-like mode lower than 0.005 dB m-1."

Yeh says that at 30 GHz, the alumina rectangular ribbon with an aspect ratio of 10:1 and a loss tangent of 0.000159 can support a low-loss transverse-magnetic-like mode with an attenuation constant of 0.0098 dB m-1, which is 120 times less than that for the dominant mode on an alumina circular rod with similar cross-sectional area and a loss tangent of 0.0001. It is also 61 times less than that for the dominant mode in a standard metallic rectangular waveguide. The researchers believe the ribbon's attenuation constant can be taken to less than 0.006 dB m-1 with a switch to the alumina material used for the circular rod.

Potential applications for the ceramic-ribbon waveguide in the 30-3000-GHz band include transporting signals for JPL's deep-space network and transporting signals for detectors, sensors, and phase-array antennas on spacecraft. There are still some fabrication issues to be addressed, though. Because the waveguide is an open structure surrounded by dry air, a proper support structure is critical. One option is a support made with plastic fishing line. Yeh describes the structure as thin nylon threads at least 10 cm apart strung across wooden rails that are 5 cm apart (far enough so that the exterior guiding fields at the ribbon edges has decayed to negligible value). The waveguide would lie on top of the nylon threads along the middle of the rails.

REFERENCE

- C. Yeh et al., Nature 404, 584 (April 6, 2000).

About the Author

Paula Noaker Powell

Senior Editor, Laser Focus World

Paula Noaker Powell was a senior editor for Laser Focus World.