Transparent oxide emits UV light

Incorporating news from O plus E magazine, Tokyo

TOKYOIn a project sponsored by the Japan Science and Technology Corporation, researchers have successfully created the world's first ultraviolet (UV) light-emitting diode (LED) using transparent oxide materials. Indium tin oxide (ITO) has long been used as a transparent oxide conductor with many applications, including liquid-crystal displays. It has not been much investigated as an optoelectronic material because oxides can only have n-type conductivity and not p-type. This group of researchers has pioneered the development of p-type transparent oxide conductors and is taking on the challenge of creating LEDs using the resulting expertise.

For the experiment, the group used strontium cuprate (SrCu2O2, or SCO for short) for the p-type material and zinc oxide (ZnO) for the n-type. Zinc oxide has a large bandgap and is a known ultraviolet-emitting material. Laser emission of ZnO by electron beam or light beam has been reported in the past, but no instances have been documented in which applying electricity has caused lasing.

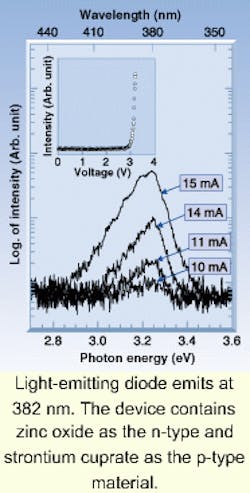

At the base of the LED is a stable zirconia substrate with a surface that is flat due to atomic ordering. An ITO film is epitaxially grown to make an electrode. Next, ZnO and SCO are grown in sequence on top using pulsed-laser deposition. A nickel electrode is then created on top of these layers. By using photolithography and reaction-ion-etching methods, mesa-structured elements are formed. Wires are attached and the current-voltage properties are determined, as well as the spectrum of the emitted light. The emitting portion of the device is 500 µm wide. Room-temperature light emission at a 382-nm wavelength is initiated at an applied voltage of 3 V (see figure). The light is thought to result from the reunion of the ZnO electrons and positive holes within the plasma.

Still in the proof-of-principle stage, the device has an energy-conversion efficiency of only 0.01%. The researchers believe that the low efficiency is caused by nonuniformities at the SCO/ZnO interface that produce many inactive

p-n junctions. Zinc oxide has tremendous light-emitting potential, so it is hoped that the efficiency will increase as the uniformity of the interface improves. The successful creation of an LED using transparent oxides may lead to the development of other novel materials for LED productionfor instance, a material made from another oxide that emits at a shorter UV wavelength.

Courtesy O plus E magazine, Tokyo