Buried land mines put in place during conflicts can remain undetected in the ground for years or decades afterward, killing and maiming civilians. Humanitarian efforts to locate and dig out some of the millions of leftover land mines are hampered partially by the inefficiency of existing electromagnetic detection techniques, which can result in as many as 300 empty holes for every discovered mine. A group at Northeastern University (Boston, MA) is pursuing ground-penetrating radar to find mines.

One of the group's members, Charles DiMarzio, who has an optics background, began to ask himself if there were optical techniques that could complement ground-penetrating radar. As a result, the group is also pioneering a mine-detection method that combines dual-frequency microwave heating with infrared (IR) imaging to spot mines in seconds, even under rough ground surfaces.

In the technique the researchers tried first, the ground and the buried land mine were heated by irradiating them with microwaves at an intensity level of roughly 1 kW/m2. When the ground surface was smooth, the location of the mine quickly became apparent in the IR as a result of two effects: direct heating of the mine at a rate different from that of the ground and a modification of the underground microwave standing wave by the mine, which causes changes in ground heating around the mine. An IR imager could then spot the mine (or, for experimental purposes, a hockey puck or bar of soap).

Getting rid of surface effects

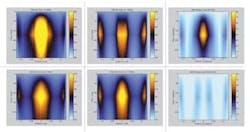

But the researchers soon discovered that any realistic variations in surface topography masked the effects produced by the mine. Their solution, described by DiMarzio at the 2000 Optical Society of America annual meeting (Oct. 22-26; Providence, RI), is to irradiate the area with microwaves of one frequency, then subtract an image taken after heating from an image taken before heating. The process is then repeated using microwaves of a second frequency. Finally, the second differential image is subtracted from the first to obtain a set of data almost entirely free of unwanted surface information (see figure). The technique works because the two microwave frequencies have similar surface effects, yet differing propagation effects; therefore, when the final subtraction is done, only the surface effects drop out.

The whole detection process takes a minute or less to complete. DiMarzio envisions a small elliptical microwave antenna mounted to a truck that can irradiate about a square meter at a time. The apparatus could even be made light enough to be hand-held, although its kilowatt-level power needs would require use of a power cord leading to a vehicle. A mercury telluride IR camera with 320 x 240 resolution and imaging at 10 µm was used for research purposes. Imaging at a wavelength of 5 µm using other types of cameras is probably feasible, says DiMarzio.

The researchers have determined that some microwave-frequency pairs are better than others and have mapped out the figure of merit from 0.1 to 3.8 GHz. The best pair appears to be 0.9 and 1.75 GHz. They are beginning a series of experiments with a 0.915- and 2.45-GHz frequency pair (although not optimum, these frequencies are commercially available and give results close to the perfect case). Future simulation and experiments will examine different angles of incidence, mine shapes and locations, soil characteristics, and effects of vegetation.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.