Researchers at Ryukoku University (Otsu, Japan) have combined phosphorescent oxides and fluorescent dyes to create an optical-fiber-based afterglow illuminator that emits in the dark without any electrical power input. The device is, in effect, a light-rechargeable flashlight.

The illuminator shares qualities with a type of fluorescent solar concentrator invented more than 20 years ago. Such a concentrator consists of one or more planar sheets of transparent dye-containing material. When sunlight strikes the sheet, much of the emitted fluorescence is channeled by the sheet via total internal reflection (TIR) to its thin edges, where it can be collected by photovoltaic cells of much-smaller total area than the sheet. Instability of the dyes under bright sunlight and absorption of the emitted light within the sheets have hampered widespread use of the concentrators.

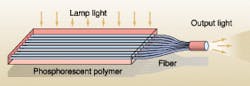

What the Ryukoku researchers have done (in addition to changing the geometry from a sheet to a fiber bundle) is to add a phosphorescent material, making light emission possible long after the excitation source has been removed. Phosphorescent materials such as strontium aluminate (SrAl2O4) have a long-lasting afterglow. The researchers first tried dispersing SrAl2O4 powder in a clear resin but found that the samples scattered light too strongly to be of much use. They then hit on the right combination—fibers doped with a fluorescent material and embedded in a polymer filled with phosphorescent powder (see figure). The polymer is of lower refractive index than the fiber to allow for TIR.

Commercially available fluorescent fibers from Bicron (Solon, OH) were used along with phosphorescent materials composed of oxides of aluminum, boron, strontium, and other elements. The researchers chose two combinations: a blue phosphorescent material with a green fluorescent fiber and a green phosphorescent material with a yellow fluorescent fiber. After being excited by light, the phosphorescent material emitted an afterglow, stimulating fluorescence in the fiber. Total internal reflection channeled light to the fiber ends.

The assembly was illuminated for five minutes by an ordinary fluorescent lamp. The green fiber emitted at a peak wavelength of 500 nm, while the yellow fiber peaked at both 590 and 630 nm. Light output of the yellow fibers was measured at 1.4 µW ten seconds after the light was turned off, an output that decayed with a time constant (1/e lifetime) of 2 min for the first 10 minutes and then a time constraint of 80 min for hours afterward. The fibers enhanced the light intensity of the phosphorescent materials up to 30 times—an action similar to that of a fluorescent solar concentrator on sunlight.

A larger fiber bundle would produce more light. Lengthening the fibers would also boost the light output, but only up to a point where output intensity saturates due to absorption. The key to still-higher emission per fiber, say the researchers, is to incorporate a fluorescent dye in which the emission wavelength is separate from its absorption band.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.