QUANTUM-CASCADE LASERS: Silicon-based QC lasers close out the terahertz gap

The quest for practical terahertz sources and detectors has been driven by the tremendous potential of these devices in medical diagnostics, security screening, and manufacturing quality control. A promising approach to the realization of terahertz semiconductor lasers is the use of intersubband transitions in quantum-cascade (QC) lasers. Although gallium arsenide/aluminum gallium arsenide QC structures can produce terahertz radiation, emission in the 30 to 40 µm range is precluded (due to the presence of polar optical phonons at nearby frequencies, whose excitation provides a prohibitively large optical absorption mechanism). In addition, fast nonradiative transitions between the laser subbands due to thermally activated phonon emission rapidly degrade population inversion, limiting the operation of these devices to cryogenic temperatures.

Researchers at Boston University have overcome these limitations by using silicon germanium (SiGe) alloys.1 By taking advantage of the nonpolar nature of these materials, and the resulting absence of photon-phonon and resonant electron-phonon scattering, the authors have demonstrated with a detailed theoretical study that high-performance SiGe QC lasers can be developed for emission throughout the terahertz spectral region. These silicon-based devices also represent a huge step forward in the demonstration of electrically pumped silicon lasers that could enable fully monolithic wafer-scale integration of photonic and electronic components.

Attempts so far to develop Si-based intersubband devices have made use of hole (p-type) intersubband transitions. Unfortunately, the intricacy of the valence-band structure of these devices makes it difficult to achieve population inversion. In an alternate approach, the researchers instead use an n-type approach that relies on electronic intersubband transitions near the local conduction-band minima (so called L valleys) of Ge/SiGe quantum wells grown on SiGe substrates. If the SiGe barriers are sufficiently thin, substantial quantum confinement is obtained for the L-valley electrons, which enables the development of far-infrared QC lasers. Use of the L valleys also allows surface-normal intersubband light emission which overcomes the low output coupling efficiency and large beam divergence of existing in-plane terahertz QC lasers based on plasmon waveguides.

Alternating wells

To maximize the electronic quantum confinement in these n-type Ge/SiGe QC structures, the device active layers consist of alternating compressively strained Ge wells and tensile strained SiGe barriers grown on SiGe substrates. The growth recipe is obtained from a careful balance of lattice constants, deformation potentials, elastic constants, spin-orbit splitting values, and conduction-band offset calculations. Thanks to the availability of high quality SiGe templates on Si(001) substrates, these QC lasers are fully compatible with the standard fabrication processes of silicon microelectronics and therefore can be seamlessly integrated with sophisticated electronic circuits.

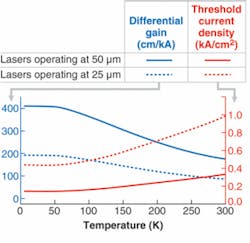

Two exemplary devices designed for emission near 50 µm (6 THz) and 25 µm (12 THz) were studied to illustrate the potential of the Ge/SiGe material to close out the existing gap in the spectral range covered by III-V QC lasers (see figure). These two devices have nonradiative lifetimes of a few tens picoseconds-an order of magnitude larger than those of typical III-V QC lasers. The resulting threshold current densities of a few hundred A/cm2 compare favorably to those of existing III-V far-infrared QC lasers.

“These results are particularly exciting as they promise a solution to two of today’s grand scientific challenges in the field of photonics, namely the demonstration of silicon-based injection lasers and the development of practical sources of terahertz light,” says Kristina Driscoll, a graduate student at Boston University and lead author of this work. “The resulting ability to combine-on a same chip-terahertz devices with complex microelectronic circuits has the potential for a revolutionary impact in many areas of modern technology, ranging from sensing and spectroscopy to imaging and communications,” adds Roberto Paiella, her research advisor and professor of electrical engineering.

REFERENCE

1. K. Driscoll and R. Paiella, J. Appl. Phys.102, 093103 (Nov. 6, 2007).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.