PHOTOVOLTAICS: Europe, U.S. set new efficiency records for triple-junction solar cells

Scientists in the United States and Europe have independently announced records for solar-cell efficiencies, adding more mile markers on the road to low-cost solar energy (see www.laserfocusworld.com/articles/311586). Researchers at the Fraunhofer Institute for Solar Energy Systems (Freiburg, Germany) reported a 39.7% efficiency for a triple-junction solar cell, exceeding their own European record of 37.6% set in July 2008.1 A group at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) announced a world record of 40.8% efficiency for an inverted metamorphic triple-junction photovoltaic (PV) device.2 Both cells are designed to be used with concentrator optics.

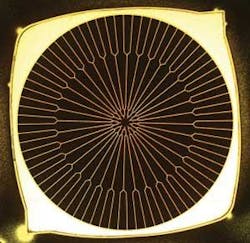

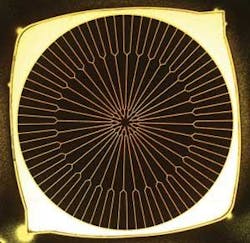

The European record involves the improvement of the contact structures of the metamorphic (or “lattice-mismatched”) solar cells. The cell structure consists of more than 30 layers, made primarily of gallium indium phosphide (GaInP), gallium indium arsenide (GaInAs) and germanium (Ge) deposited on a Ge substrate. The contact grid on the front side of the solar cell conducts current through a network of thin wires that radiate from the middle of the cell to the edge, where a 50 µm gold wire gathers the current. The wire veins must be as thin as possible so as not to block impinging sunlight on the cell below, but thick enough to carry large currents at a low resistance (see figure). Frank Dimroth, head of the III-V - Epitaxy and Solar Cells group at the Fraunhofer Institute, says the optimized wire width minimizes reflection losses and is the difference between the recent 37.6% number at an irradiance of 1700 “suns” and the 39.7% number at 300 suns, in which one sun is equal to the illuminance that typically hits Earth per square meter, directly overhead on a sunny day, or 1 kW/m2.Like the European design, NREL’s most recent work is based on a metamorphic triple-junction solar cell, but with a twist on a twist. The first twist was the “inverted” metamorphic triple-junction solar cell, designed by NREL’s Mark Wanlass in 2005. Wanlass and colleagues grew GaInP, GaAs, and metamorphic GaInAs junctions in reverse order on a GaAs wafer, flipped it over, and removed the wafer to create a very thin and lightweight design with superior performance and low cost.

A team led by NREL senior scientist John Geisz took that design one step further. They used alloy compositions with three different lattice constants to optimize the junction energies for three different band gaps. The efficiency of a 0.1 cm2 device reached 40.8% efficiency, measured at 326 suns.

New design has potential

Because the 40.8% value is only a tenth of a percentage point above the last record of 40.7% achieved at Spectrolab (Sylmar, CA), the uncertainty makes it difficult to differentiate which one is actually higher, admits Geisz. “Our 40.8% result uses a very different structure than their more conventional design,” he explained. “Our design has the potential to reach efficiencies that are significantly higher than the potential efficiencies of the Ge-based designs. The previous record was achieved by maturing and perfecting the older design, while our new record is an initial result of trying a new approach, leaving plenty of room for improvement.”

In July 2007, the University of Delaware reported a solar-cell efficiency of 42.8%, independently confirmed by the government-run PV Cell and Module Performance group at NREL (the same lab also independently confirmed the NREL results). Why then is 40.8% a new record? According to Keith Emory, device performance manager at the NREL testing lab, the difference is that the Delaware efficiency number is partly theoretical—the sum of several individual tests of three different solar cells over six months, assuming ideal optics. This result is nonstandard in that the Delaware cells were tested at different times and not as a group, says Emory. “The fact that Geisz’s group actually stacked the pieces together for testing as a single module is what’s impressive here.”

REFERENCES

- www.ise.fhg.de

- J.F. Geisz et al., Appl. Phys. Lett. 93, 123505 (2008).

About the Author

Valerie Coffey-Rosich

Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.