Large laser tackles nuclear-waste problem

One of the major problems of nuclear power lies in the management and disposal of high-level radioactive waste. A recent meeting funded by the Engineering and Physical Sciences Research Council (Swindon, England) highlighted this problem, with the organizers saying that the problem of nuclear-waste disposal has proven to be one of the most intractable of all issues in U.K. technology policy.

One approach to the problem involves finding methods to transmute the nuclei of long-lived isotopes into nuclei with much shorter half-lives. This has been demonstrated by bombarding the waste isotopes with neutrons from a reactor or even from a particle accelerator. Now, European physicists have demonstrated a laser-driven approach to transmutation that has converted iodine-129, which has a half-life of 15.7 million years, into iodine-128, with a half-life of a mere 25 minutes.

In the iodine process, a laser-generated gamma ray is absorbed into the iodine-129 nucleus, which releases a neutron to undergo transmutation to iodine-128. The scientists, from the U.K. and Germany and led by Ken Ledingham from the University of Strathclyde (Glasgow, Scotland), used the Vulcan petawatt laser at the Rutherford Appleton Laboratory (Didcot, England). The Nd:glass laser produces 0.7-ps, 360-J laser pulses at a wavelength of around 1 µm. Focusing this light with a 1.8-m-focal-length off-axis parabolic mirror to a 5.5-µm spot size produces an intensity on the order of 5 × 1020 W/cm2 at the target.

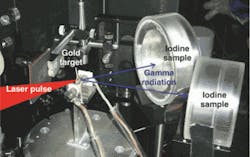

The target is solid gold with dimensions 5 × 5 × 4 mm; the high-intensity laser beam drives electrons into the target at relativistic energies, generating high-brightness beams of gamma rays, protons, neutrons, and heavy ions.

Two iodine samples were positioned along the laser and target normal directions, behind the gold target (see figure). The samples were prepared from waste solution from a fuel-processing facility. The iodine was extracted by producing a lead salt. This powder was compacted in a 55-mm-diameter aluminum can, which was further encapsulated in a vacuum-tight Plexiglas container. The samples contained around 40 g of iodine, with an isotopic composition of 85% iodine-129 and 15% iodine-127.

The iodine samples were analyzed using germanium detectors before and after laser irradiation of the gold target. After radiation, the characteristic peaks of iodine-128 were clearly visible on the detectors; the half-life was measured and confirmed to be the 25 minutes expected. Measurements from this experiment demonstrated that a single laser shot in this setup can generate about 3 million iodine-128 nuclei. A similar experiment carried out on the short-pulsed tabletop laser at the University of Jena (Jena, Germany; see "Tabletop laser induces transmutation," p. 13) used a comparable laser intensity, but a lower pulse energy of about a joule, generating a much lower rate of approximately two nuclei of iodine-128 per laser shot.

"We have shown that laser-driven photo-transmutation is a feasible method for experimental research into transmutation reactions," says Ledingham. "This has potential applications in medicine and nuclear-waste management. A new generation of compact high-intensity tabletop lasers is currently being designed in several laboratories using novel technology such as optical parametric chirped-pulse amplification. Several of these laser systems will be geared toward applications such as medical-isotope production and transmutation studies of long-lived isotopes. Now we need to scale up our methods so that we can deal with the sort of volumes likely to be produced by the nuclear industry in the future."