The classic model of fuel combustion in diesel engines is incorrect according to researchers at Sandia National Laboratories (Livermore, CA). The group is using a specially modified diesel engine and a combination of planar laser Rayleigh-scatter imaging and planar laser-induced incandescence (LII) imaging to study diesel fuel-jet penetration, vaporization, and mixing-process dynamics as well as relative soot concentrations and particle-size distributions in the combusting fuel jet.

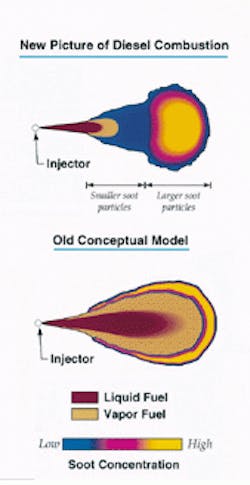

Prior to the testing program, diesel-engine designers thought injected liquid-phase fuel penetrated far into the combustion chamber and that both liquid-phase and vapor-phase diesel fuel were present in the combustion zone. They also believed that the combusting fuel jet consisted of a pure-fuel core with a diffusion flame around the periphery and that soot particles occurred on the fuel-rich side of the diffusion flame in a shell around the periphery.

Laser imaging tests demonstrate, however, that, under typical conditions, all the liquid diesel fuel vaporizes within 25 mm of the injector and that the fuel in the main combustion zone is in the vapor phase. Quantitative fuel-vapor-concentration measurements show that, just downstream of the maximum liquid penetration, the fuel vapor is uniformly mixed with air.

Imaging of soot formation indicates that the soot actually occurs throughout the cross section of the combusting fuel jet, starting just downstream of the liquid-fuel region. Both the concentration and particle size of the soot increase toward the leading edge of the jet, with the highest concentrations and largest soot particles occurring at the front of the jet (see Fig. 1). Clusters of large soot particles from this region persist late into the combustion event, which means they might never oxidize and may eventually come out of the engine exhaust pipe.Combustion imaging

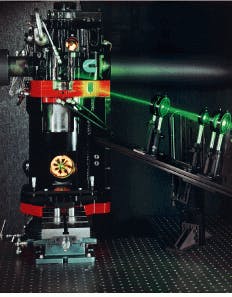

The insights into fuel combustion have been obtained using a diesel engine modified with quartz windows to allow observation of the combustion process (see Fig. 2); the engine`s optical portholes enable the researchers to direct a two-dimensional "sheet" of laser light into the combustion chamber. Laser-induced incandescence imaging (imaging of induced thermal radiation) provides planar images of relative soot concentration in the cylinder, while Rayleigh-scatter imaging (two-dimensional imaging of submicroscopic particles) is used to make quantitative fuel-vapor concentration images, and, when done in conjunction with LII, it also provides soot particle-size distribution.

The laser source is a frequency-doubled Nd:YAG laser, which, in LII imaging, heats the soot from flame temperature (~2200 K) to about 4500 K during an 8-ns pulse. Two-dimensional LII images are generated using an intensified video camera to collect the thermal radiation from the laser-heated soot, which is more incandescent than the surrounding soot--especially at shorter wavelengths. Special filters are used to isolate the shorter-wavelength light and to reject elastically scattered laser light. In addition, the gate of the camera is synchronized with the laser pulse to eliminate the natural flame luminosity.

The diesel-engine studies are being conducted at Sandia as a cooperative research and development agreement (CRADA) between the US Department of Energy and Cummins Engine Company (Columbus, IN), the world`s largest producer of high-power (> 200 horsepower) diesel engines. Results from the program are used to improve computer modeling of the diesel fuel combustion process and enable Cummins to design more environmentally friendly diesel engines without reducing their performance.

About the Author

Stephen G. Anderson

Director, Industry Development - SPIE

Stephen Anderson is a photonics industry expert with an international background and has been actively involved with lasers and photonics for more than 30 years. As Director, Industry Development at SPIE – The international society for optics and photonics – he is responsible for tracking the photonics industry markets and technology to help define long-term strategy, while also facilitating development of SPIE’s industry activities. Before joining SPIE, Anderson was Associate Publisher and Editor in Chief of Laser Focus World and chaired the Lasers & Photonics Marketplace Seminar. Anderson also co-founded the BioOptics World brand. Anderson holds a chemistry degree from the University of York and an Executive MBA from Golden Gate University.