Surface-discharge lamp zaps away lead paint

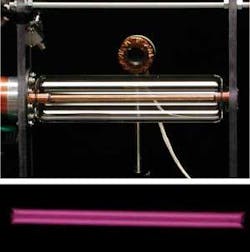

Engineers at Phoenix Science and Technology (Chelmsford, MA) have demonstrated an optical approach to cleaning up the stubborn problem of lead paint in older housing; in the technique, short, intense pulses of light vaporize the paint’s surface layer, which can be vacuumed and collected in a filter. Although pulsed lasers can strip paint from aircraft, they are too expensive and complex to use for removing lead paint from housing, says Phoenix founder Ray Schaefer, while flashlamps don’t generate pulses that are short and intense enough. But Schaefer has developed a new type of lamp (top) in which a surface discharge (bottom) forms along a dielectric cylinder in the center of a xenon-filled tube. Separating the discharge from the outer glass tube allows the surface-discharge lamp to operate at higher energy and generate pulses shorter than 100 µs.

Laboratory tests of a paint-removal system built around the lamp showed that zapping a piece of wood coated with two coats of dark-green lead paint reduced lead levels from 1.7 to 0.44 mg/cm2, meeting Environmental Protection Agency requirements. White lead paint absorbs much less visible light, but the lamp has peak emission in the UV, where all lead paints absorb strongly. Phoenix has a follow-up grant from the Department of Housing and Urban Development to develop a truck-mounted system for tests with a lead-abatement program in Lowell, Massachusetts. Contact Ray Schaefer at [email protected].